Why is a Magnetic Drill Essential in Construction and Industrial Projects?

Why is a Magnetic Drill Essential in Construction and Industrial Projects?

Introduction

In construction and industrial projects, the use of precise and professional tools plays a crucial role in quality, safety, and execution speed. Advanced tools not only improve productivity but also reduce human errors. The necessity of a magnetic drill in these projects is increasingly recognized due to its high accuracy, time efficiency, and cost reduction.

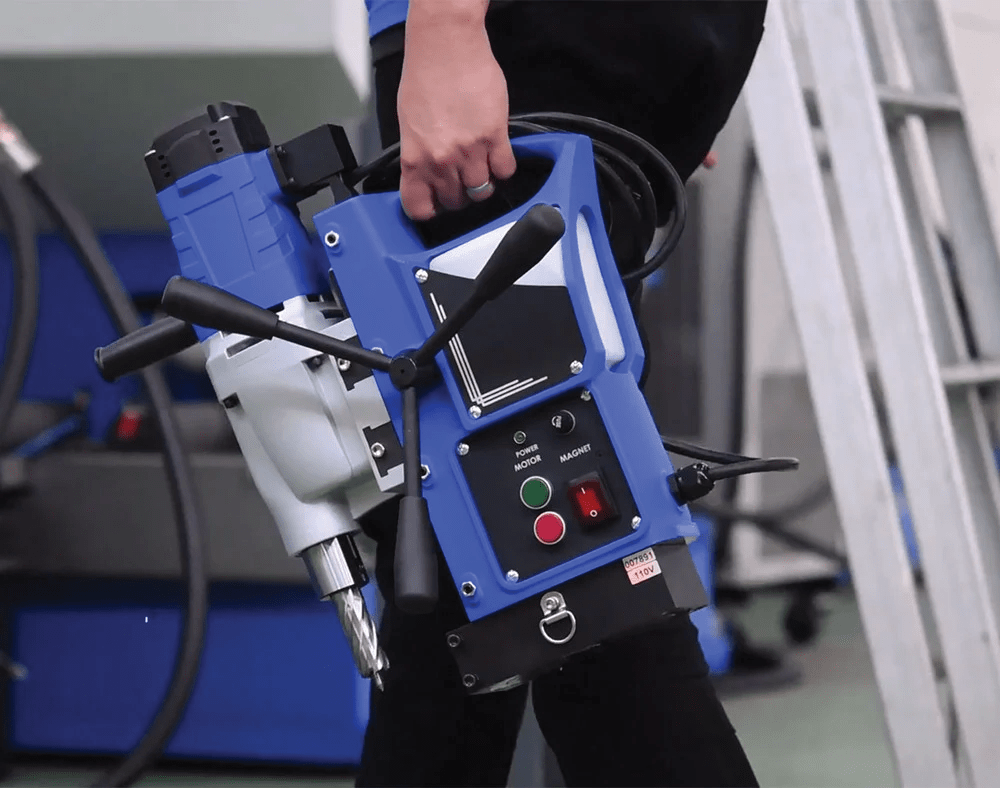

An industrial magnetic drill, equipped with a magnetic base, is firmly fixed on metal surfaces, allowing accurate, fast, and stable drilling. Thanks to its portability, high safety standards, and ability to lower operational costs, this tool has become one of the most widely used devices in construction, industrial equipment installation, and heavy industries. In the following sections, the applications and advantages of the magnetic drill in construction and industrial projects will be discussed.

The Necessity of Magnetic Drill in Construction and Metal Industries

In large construction and metalworking projects, there are often heavy and bulky metal parts that are difficult or even impossible to move for drilling. In the past, handheld drills were used to create holes in these pieces, but they lacked sufficient accuracy and consumed too much time. The industrial magnetic drill, with its portability and ability to be fixed directly at the workpiece location, has solved this problem. The magnetic base of the device adheres firmly to metal surfaces and prevents vibration, which significantly improves drilling accuracy.

Moreover, the use of an industrial magnetic drill increases productivity and reduces operational costs. In industrial projects where precise scheduling and high efficiency are critical, neglecting the necessity of magnetic drill leads to higher labor costs and reduced execution accuracy.

The Necessity of Magnetic Drills

Key Applications in Real Projects

The applications of the magnetic drill in industrial and construction projects are extensive. This device is not only used in construction but also in the oil, gas, and petrochemical industries, as well as in industrial facilities and steel structures.

Building and Steel Structures

In steel frameworks of buildings and bridges, bolted connections require precise and well-aligned holes. The industrial magnetic drill enables contractors to create accurate holes directly on-site without moving heavy components.

Using a magnetic drill in construction projects reduces measurement errors and increases installation speed. Due to its high precision, the quality of drilling improves, and bolted connections are executed with much greater accuracy.

Industrial Facilities and Equipment Installation

In factory and facility industries, drilling holes in metal structures during the installation of heavy machinery and equipment is unavoidable. The industrial magnetic drill is the best choice for drilling chassis, metal bases, and platforms used for heavy equipment installation.

One of the key advantages of this device is that it can be transported directly to the equipment site, allowing drilling exactly where needed. This saves transportation costs for heavy components and reduces project execution time.

Drilling in Oil, Gas, and Petrochemical Industries

In oil and gas industries, where thick pipes, pressure vessels, and metallic equipment are widely used, precise and safe drilling is highly important. Due to its power and ability to adhere firmly to metal surfaces, the industrial magnetic drill is an ideal choice for this sector.

Other applications include drilling on drilling rigs, oil and gas pipelines, and offshore structures. Pneumatic and spark-proof magnetic drill models are also widely used in flammable environments, preventing risks caused by electrical sparks.

Construction and Maintenance of Large Structures (Bridges, Towers, Warehouses)

In large-scale projects such as steel bridges, industrial warehouses, transmission towers, and telecommunication structures, creating precise holes in metal parts is a critical stage of execution. The industrial magnetic drill plays an essential role in accelerating execution and reducing drilling errors.

In maintenance and repair works, the magnetic drill is also a vital tool. For installing reinforcement plates on deteriorated structures or replacing damaged parts, the drill enables fast and safe drilling at heights and under difficult conditions.

Key Applications of Magnetic Drills

Advantages of Magnetic Drill Compared to Traditional Methods

- Increased productivity and reduced labor costs

- High precision and prevention of drilling errors

- Greater safety during work and reduced risk of industrial accidents

- Portability and usability in difficult and hard-to-reach areas

- Reduced maintenance costs and extended service life of industrial equipment

By addressing these advantages, the necessity of magnetic drill in modern construction and industrial projects becomes even clearer.

The Necessity of Choosing the Right Magnetic Drill for Each Project

Selecting the right industrial magnetic drill for each project has a major impact on efficiency and productivity. When purchasing, pay attention to the following points:

- Motor power and drilling capacity: It must match the type and thickness of the metal components.

- Magnetic base strength: For working at heights or on vertical surfaces, strong magnetic adhesion is essential.

- Weight and portability: In mobile projects, lighter and more compact models are recommended.

- Safety features and technology: Some models include a magnetic force sensor, an automatic shut-off system, and variable speed adjustment, making the device safer and more efficient to use.

Conclusion

In short, the industrial magnetic drill is one of the most essential tools in construction and industrial projects. By enhancing drilling accuracy, increasing execution speed, and ensuring safety, it plays a vital role in the success of the construction and metal industries.

In the end, to fully benefit from this tool, it is recommended to purchase it from trusted and specialized suppliers. Rahmani Magnetic Drill Store, as a professional supplier, offers various industrial magnetic drills along with after-sales services and expert consultation. With the correct choice of magnetic drill, project performance and productivity can be maximized.