Multi-Speed vs Single-Speed Magnetic Drill: Differences, Applications & Professional Choice

Multi-Speed vs Single-Speed Magnetic Drill: Differences, Applications & Professional Choice

Introduction

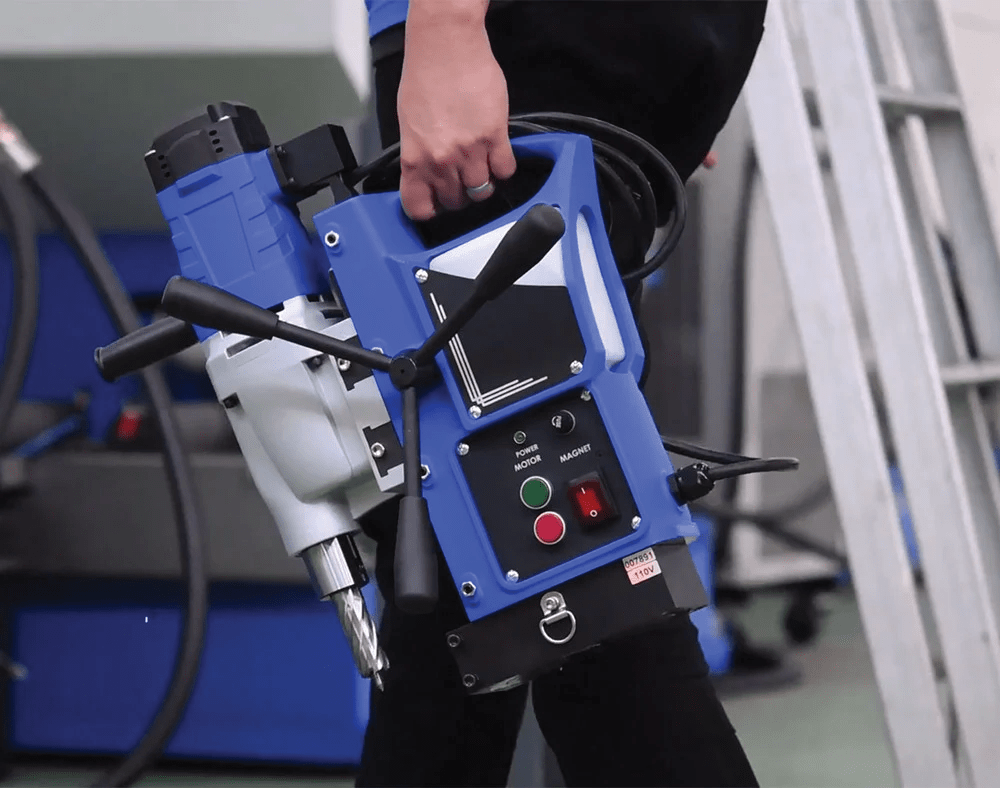

When it comes to a multi-speed magnetic drill, many professional users and even workshop managers are still unsure about how it differs from a single-speed model, and more importantly, when this difference truly matters. In a magnetic drill, the cutter’s rotation speed is determined not only by motor power but also by the gearbox design, torque transmission system, and speed control mechanism. These elements define what type of metal the drill can penetrate, at what diameter, and how efficiently it can operate without damaging the cutter or the work surface.

Simply put, a multi-speed magnetic drill gives the user greater control over both speed and torque; a crucial advantage in heavy-duty projects such as steel structure construction, industrial frameworks, and refinery installations. In contrast, single-speed drills are designed for routine, repetitive drilling tasks or for drilling into medium-thickness materials. In the following sections, we’ll explore the structural differences, performance characteristics, advantages, and limitations of both types to help you choose the ideal magnetic drill for your specific needs.

What Is a Multi-Speed Magnetic Drill and Why Has It Become So Popular?

A multi-speed magnetic drill is one of the most advanced types of magnetic drilling machines, allowing the operator to adjust the drilling speed across several levels. In these machines, the motor is connected to the spindle through a multi-stage gearbox, giving the user the flexibility to select the optimal speed according to the metal type and hole diameter. For instance, when drilling into hard steel surfaces, a lower speed with higher torque is required, while for thin sheets or softer alloys, a higher speed delivers better performance.

This feature has made multi-speed magnetic drills the first choice in industrial workshops; a single machine can serve multiple purposes. Without changing the tool, the operator can easily switch gearbox settings to perform both heavy-duty drilling on thick steel and faster operations on lighter sheets. This flexibility, combined with superior accuracy, is the main reason behind the growing popularity of multi-speed models among engineers working on steel structures, industrial frames, and refinery projects.

Unlike older single-speed models, modern multi-speed magnetic drills often feature two- or three-stage metal gearboxes, and in some brands such as Euroboor and Eibenstock, even electronic Variable Speed Control systems. These advanced systems allow smooth, continuous speed changes during operation without putting stress on the motor or cutter. As a result, a multi-speed magnetic drill is not just a drilling tool; it is an intelligent machine that adapts to different conditions, significantly enhancing efficiency, safety, and tool lifespan.

What Is a Multi-Speed Magnetic Drill?

What Is a Single-Speed Magnetic Drill and What Are Its Advantages and Limitations?

A single-speed magnetic drill represents the simpler and more fundamental generation of magnetic drills, typically operating at a fixed speed. In these machines, the motor is directly connected to the drive spindle, without a multi-stage gearbox or electronic speed control system. This makes their design simpler, more affordable, and easier to maintain.

In projects where the work type and material thickness remain consistent, such as mass production of metal components or repetitive drilling in steel structure workshops, single-speed magnetic drills deliver highly satisfactory performance. Since the user doesn’t need to adjust the speed frequently, attention can remain on accuracy, perpendicular alignment, and safety.

From a technical perspective, these drills are often designed for HSS (High-Speed Steel) cutters, which perform efficiently at medium speeds. For materials with thicknesses between 8 and 25 mm, a single-speed drill can produce smooth, uniform cutting without requiring special adjustments.

Additionally, due to the simpler power transmission system, energy loss is minimized, and many models provide higher initial torque compared to multi-speed drills. This makes it easier to start drilling on rough or rusted surfaces.

However, there are also clear limitations. A single-speed magnetic drill may struggle with hard alloys or stainless steel because a fixed speed doesn’t always match the material’s resistance. Moreover, when drilling larger holes or using TCT cutters, high speed can cause the cutting edges to overheat. Therefore, single-speed models are ideal for workshops with consistent, repetitive operations, not for projects with diverse metal types or varying thicknesses.

What Is a Single-Speed Magnetic Drill?

Comparison Between Multi-Speed and Single-Speed Magnetic Drills in Industrial Projects

Difference in Performance and Speed Control

The main distinction between a multi-speed magnetic drill and a single-speed model lies in how each manages motor power and flexibility under varying working conditions. In multi-speed models, the operator can adjust gears or use electronic controls to set the optimal speed and torque depending on the metal type, material thickness, and cutter diameter. For example, when drilling through hard steel or heavy I-beams, using a lower speed increases torque and reduces stress on the cutter edges. Conversely, when working on thinner sheets or softer alloys, higher speed enables faster chip removal and a smoother finish.

Single-speed models lack this flexibility; the operator must rely on manual pressure adjustments or switch to a different cutter type. In large-scale projects, this limitation can lead to reduced productivity, excess heat generation, and less drilling precision.

Difference in Torque, Accuracy, and Stability

In terms of torque, multi-speed magnetic drills generally produce higher power at lower speeds, making them ideal for workshops dealing with alloyed steels or thick components. On the other hand, single-speed drills are lighter because they lack multi-stage gearboxes, which makes them easier to transport and handle, especially when working at heights or in confined spaces. The weight difference between the two types typically ranges from two to four kilograms, an important factor for repetitive or overhead work.

When it comes to precision, multi-speed models outperform thanks to smoother speed transitions and reduced vibration. The result is cleaner holes, lower operating temperatures, and extended tool life, particularly when using large-diameter TCT or HSS cutters.

Economic Analysis and Industrial Choice

The price gap between the two types usually ranges from 20% to 40%. However, in projects involving various metals, thicknesses, or drilling diameters, this cost difference is quickly offset by longer cutter life and reduced downtime. In heavy industries such as oil and gas or steel structure construction, multi-speed magnetic drills from brands like Euroboor and Eibenstock are the top choice due to their power and versatility. Conversely, for lighter applications and small workshops, single-speed models from Jepson or Bosch remain an economical and reliable option.

How to Choose the Right Magnetic Drill for Your Workshop

Choosing between a multi-speed magnetic drill and a single-speed one isn’t just about motor power or price. The final decision should depend on your project type, material, workload, and the operator’s skill level. Below are the main factors professionals consider before purchasing a magnetic drill.

Type of Work and Material Thickness

If your projects involve drilling into I-beams, thick steel plates, or alloyed metals, a multi-speed magnetic drill is the better option because it allows torque and speed adjustment according to the metal’s resistance. However, for workshops mainly working with thinner sheets or light structures, a single-speed model is often sufficient.

Workload and Operation Variety

In high-capacity workshops that perform dozens of drillings per day, a multi-speed model ensures better productivity since it can adapt to different metals without tool or machine changes. In contrast, smaller projects or light-duty contractors benefit more from single-speed drills, which cost less and require minimal maintenance.

Operator Skill and Experience

Multi-speed drills require a deeper understanding of optimal drilling speeds. The operator must know the right combination of rotation speed and pressure for each metal type. For beginners or workshops with less experienced staff, a single-speed model reduces user error and tool wear.

Budget and Ownership Cost

While multi-speed magnetic drills have a higher initial cost, they quickly pay off in workshops that handle diverse materials and complex projects. Conversely, for repetitive and simple tasks, a single-speed model offers better value with lower purchase and service costs.

Practical Selection Summary

Use this simple guide for your final choice:

• If your projects are light, repetitive, and uniform → choose a single-speed magnetic drill.

• If your projects are heavy, varied, and long-term → choose a multi-speed magnetic drill.

• If you value flexibility, precision, and longer cutter life → the multi-speed model is the professional choice.

How to Choose the Right Magnetic Drill for Your Workshop

Conclusion: Which Magnetic Drill Is the More Professional Choice?

Answering whether a multi-speed magnetic drill is better than a single-speed one ultimately depends on workshop conditions and project type. If the goal is to perform simple, repetitive drilling tasks with consistent material thickness, single-speed models remain economical, durable, and reliable options. However, in large-scale projects where metal types, material thickness, and cutter diameters constantly vary, multi-speed drills deliver far greater efficiency and performance.

From a technical standpoint, a multi-speed magnetic drill offers long-term advantages that become clear over time:

• Precise control of speed and torque for different metals (from mild steel to stainless steel)

• Reduced cutter wear and extended tool lifespan

• Lower vibration, temperature, and risk of hole misalignment

• Compatibility with a wider range of cutter diameters and applications

While single-speed drills appear simpler, this simplicity can become a limitation in demanding conditions. For instance, drilling large holes in thick steel at a fixed speed may lead to overheating and poor-quality cuts — a problem solved only through speed adjustment.

In Iran’s market, brands like Euroboor, Eibenstock, FE Powertools, Jepson, and Bosch offer both types. For workshops seeking precision and stability, the multi-speed versions are the smarter choice, while lighter and portable single-speed models remain practical for smaller-scale or mobile operations.

Ultimately, your decision should balance project type, operator skill, and available budget. If your goal is higher productivity, precision, and longer equipment life, the multi-speed magnetic drill is the professional’s choice.

Contact for Expert Consultation

If you’re still uncertain which model fits your workshop best, the specialists at Rahmani Magnetic Drill Store are ready to help. Visit drill-magnet.com to explore authentic models from leading global brands or contact the sales team for personalized advice and technical guidance.