Why Should Magnetic Drill Repairs Be Done by a Specialized Center?

Why Should Magnetic Drill Repairs Be Done by a Specialized Center?

Introduction

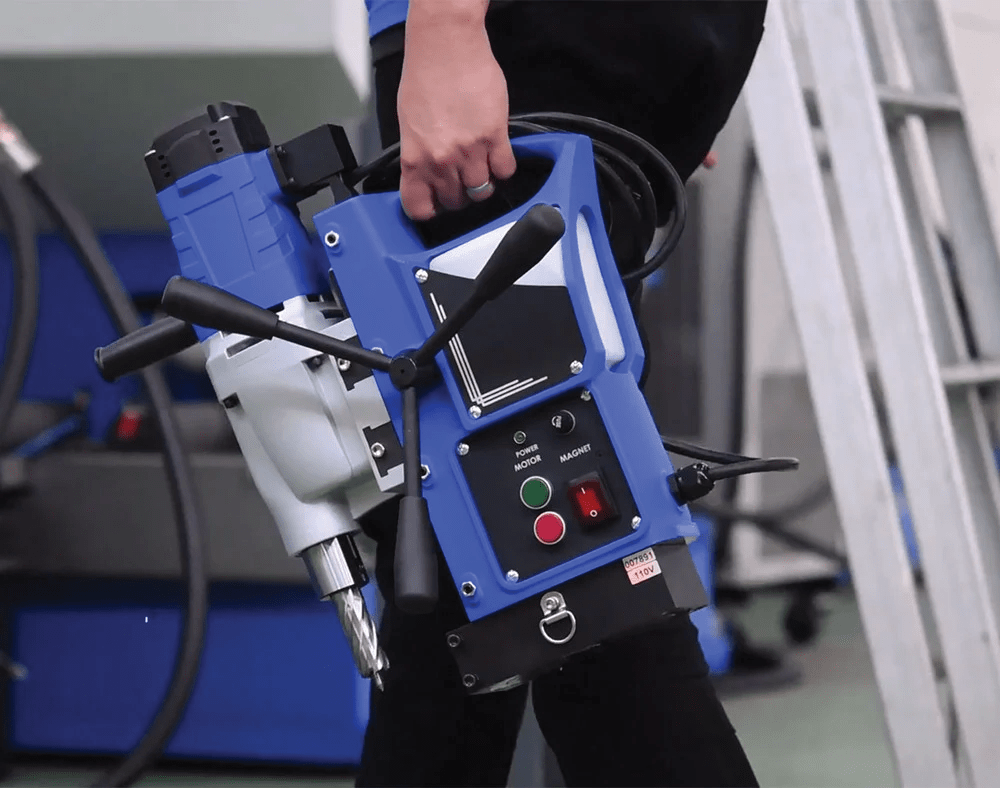

The magnetic drill is one of the most essential machines in industrial and metalworking projects. Due to its high precision and ability to drill through thick steel sections, it holds a vital place in modern industries. However, just as its performance is crucial, proper maintenance and repair are equally important. Even a small malfunction in the motor, gearbox, electrical system, or magnetic base can halt an entire project.

Many users, when facing machine failure, hand over their equipment to general repair technicians. Yet, the magnetic drill is a highly specialized tool, and its repair requires technical expertise, precision instruments, and genuine spare parts. This is where the importance of a magnetic drill repair center becomes evident.

In this article, we will explore why choosing a specialized center for repairing this tool is essential, what risks unprofessional repairs pose, what features define a reliable service provider, and finally, why Rahmani Workshop stands out as one of the most trusted magnetic drill repair centers in Iran for industrial users and professionals.

Difference Between a General Repairman and a Specialized Magnetic Drill Repair Center

Many users believe that any regular tool repairman or motor technician can fix a magnetic drill when it malfunctions. However, the magnetic drill is structurally and functionally very different from ordinary power tools. These differences make it essential that only a specialized magnetic drill repair center provides proper and standard service.

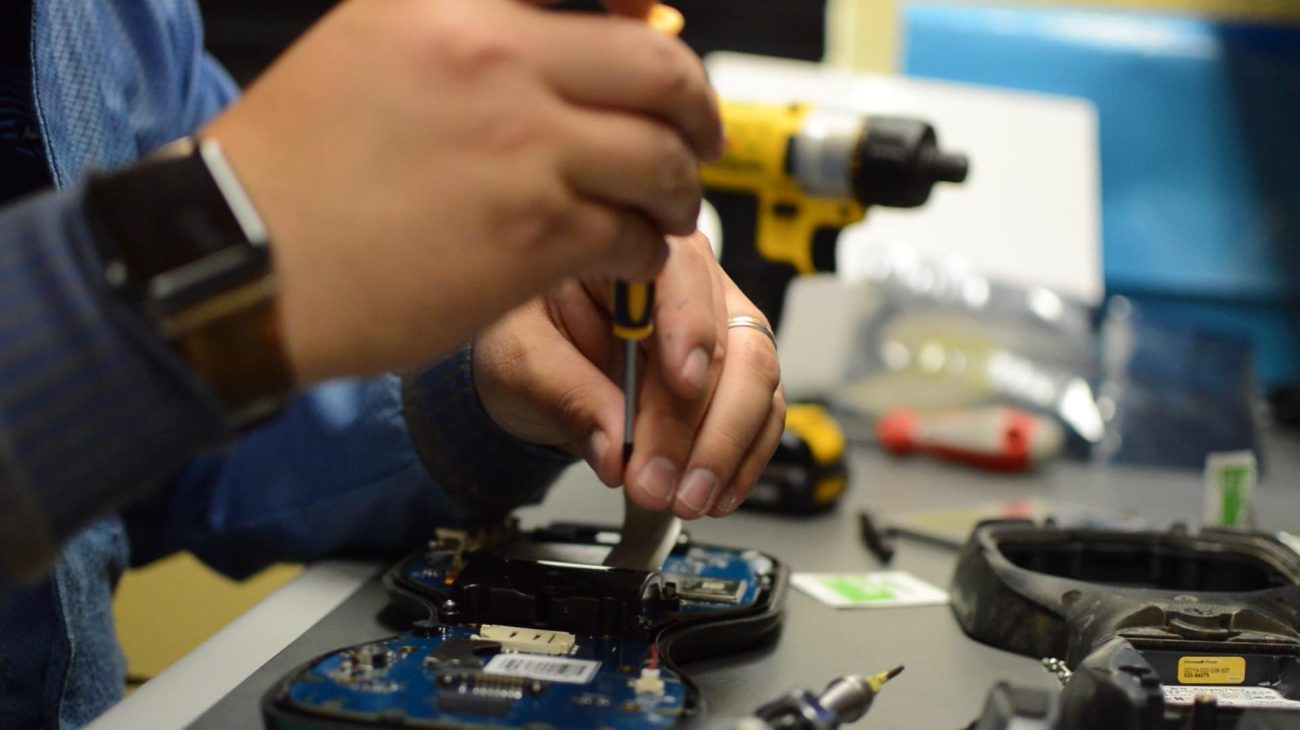

Technical Knowledge and Practical Experience

A general repairman may understand the basics of electric motors or circuits, but a magnetic drill is a complex system consisting of a motor, gearbox, magnetic base, control board, and precision chuck. Specialized repair centers are familiar with the internal structures of different brands—such as Euroboor, Bosch, and BDS—and can identify the root cause of issues accurately.

Precision Tools and Diagnostic Equipment

Repairing a magnetic drill requires professional tools such as magnetic base calibration machines, current testers, and gearbox alignment devices. A general repairman typically lacks such equipment and relies on basic, non-standard repair methods that may cause further damage instead of solving the issue.

Original Spare Parts

One of the key differences lies in parts replacement. Specialized repair centers for magnetic drills have access to genuine spare parts from reputable brands. In contrast, general repairmen often use imitation or counterfeit components that might temporarily fix the issue but ultimately shorten the machine’s lifespan.

Warranty and Service Guarantee

A professional magnetic drill repair center usually provides guaranteed service. This means that if the same problem reoccurs, the customer can have it fixed again without additional costs. General repairmen, however, rarely offer such assurance or follow-up service.

Difference Between a General Repairman and a Specialized Magnetic Drill Repair Center

Risks of Unprofessional Magnetic Drill Repair

At first glance, taking a magnetic drill to a non-specialized technician may seem simple and inexpensive. However, experience shows that this decision can lead to serious, and sometimes irreversible, damage.

Damage to the Motor and Gearbox

The motor and gearbox are the beating heart of a magnetic drill. In unprofessional repairs, lubrication and gearbox adjustment are often done incorrectly. This leads to excessive pressure on the gears, causing them to wear out or break in a short time. Replacing the gearbox is extremely costly—sometimes even more expensive than the drill itself.

Reduced Magnetic Power

The magnetic base of the drill must be calibrated accurately. If the technician lacks testing and calibration tools, the magnet will lose its holding strength. This issue is dangerous because it causes the drill to slip during drilling, leading to potential material damage or even injury.

Use of Counterfeit Parts

Unqualified repairers often use cheap, low-quality components. For example, fake motor brushes or non-original switches not only have a short lifespan but can also damage the electrical circuit of the device. Eventually, these issues result in higher repair costs compared to a proper magnetic drill repair center.

Increased Machine Downtime

When the drill is in the hands of an untrained technician, a simple fix can turn into a long, ineffective repair process. This downtime disrupts industrial projects and causes financial losses for the user.

Real Example

In one industrial workshop, a Euroboor magnetic drill was sent to a general repairman due to a faulty power switch. Instead of installing the original component, he used a similar but incompatible switch, which caused the control board to burn out. The repair cost is multiplied several times. Had the drill been taken to a specialized magnetic drill repair center like Clinic Abzar from the start, the issue could have been solved quickly and cheaply with a genuine replacement part.

Risks of Unprofessional Magnetic Drill Repair

Why Rahmani Is the Best Magnetic Drill Repair Center

When it comes to magnetic drill repair, it’s not just about fixing a simple fault. These machines are highly specialized tools used in sensitive projects within the construction, oil and gas, and metal industries. Even a small mistake in repair can lead to costly damages or serious safety risks. That’s why choosing a trusted magnetic drill repair center is essential.

Expertise in Leading Global Brands

Rahmani has been exclusively servicing major brands such as Euroboor, Bosch, and BDS for many years. This means that the technicians fully understand the mechanical and electrical systems of these tools and can accurately identify the source of any malfunction.

Use of Genuine Spare Parts

All repairs at Rahmani are carried out using genuine, original parts—from motor brushes and electrical switches to gearboxes and magnetic bases. These parts are directly sourced from authorized distributors, ensuring that every repaired drill delivers the same performance as when it was new.

Advanced Diagnostic and Calibration Equipment

Rahmani is equipped with state-of-the-art testing and calibration systems that allow precise inspection of magnetic strength, gearbox health, and electrical circuits. As a result, repairs are not only faster but also completed with higher precision and professional standards.

Guaranteed Service

All magnetic drill repair services at Rahmani come with a full warranty backed by Clinic Abzar. This means that if the same issue reoccurs, the repair is performed again at no additional cost. Such assurance has built strong trust among customers who confidently send their machines for service.

Technical Consultation and Support

One of Rahmani’s key strengths is its free customer consultation. Whether before the repair (to decide on replacement parts) or after the service (to ensure correct machine operation), the technical team is always available to provide guidance and professional advice.

Why Rahmani Is the Best Magnetic Drill Repair Center

Conclusion: Be Careful When Choosing a Specialized Magnetic Drill Repair Center

Repairing a magnetic drill is not a simple or general task. These machines consist of a motor, gearbox, electrical circuit, and magnetic base — each requiring specific knowledge and specialized tools. Entrusting such work to unqualified technicians can turn minor issues into serious and costly breakdowns.

A reputable magnetic drill repair center not only restores the machine to standard condition but also, by using genuine parts and precision tools, significantly increases its service life.

Rahmani Workshop, as one of the leading specialized magnetic drill repair centers in Iran, stands out with its extensive experience in major brands such as Euroboor, Bosch, and BDS, direct access to original spare parts, and a team of trained technicians.

If your magnetic drill needs repair or regular servicing, contact Rahmani Service Center today. Our technical team is ready to repair your machine with the highest quality and return it to full performance for heavy-duty and precision projects.