Why Does a Mag Drill Slip on 4mm Plate? (Backing Plate Technique & Magnetic Saturation Calculation)

Why Does a Mag Drill Slip on 4mm Plate? (Backing Plate Technique & Magnetic Saturation Calculation)

Introduction

This article is your expert guide to understanding the phenomenon of magnet adhesion on thin plates, identifying force-reducing factors, and providing step-by-step technical solutions. We prove with engineering language how, with a simple process change, you can increase your drilling safety and efficiency by up to 100%.

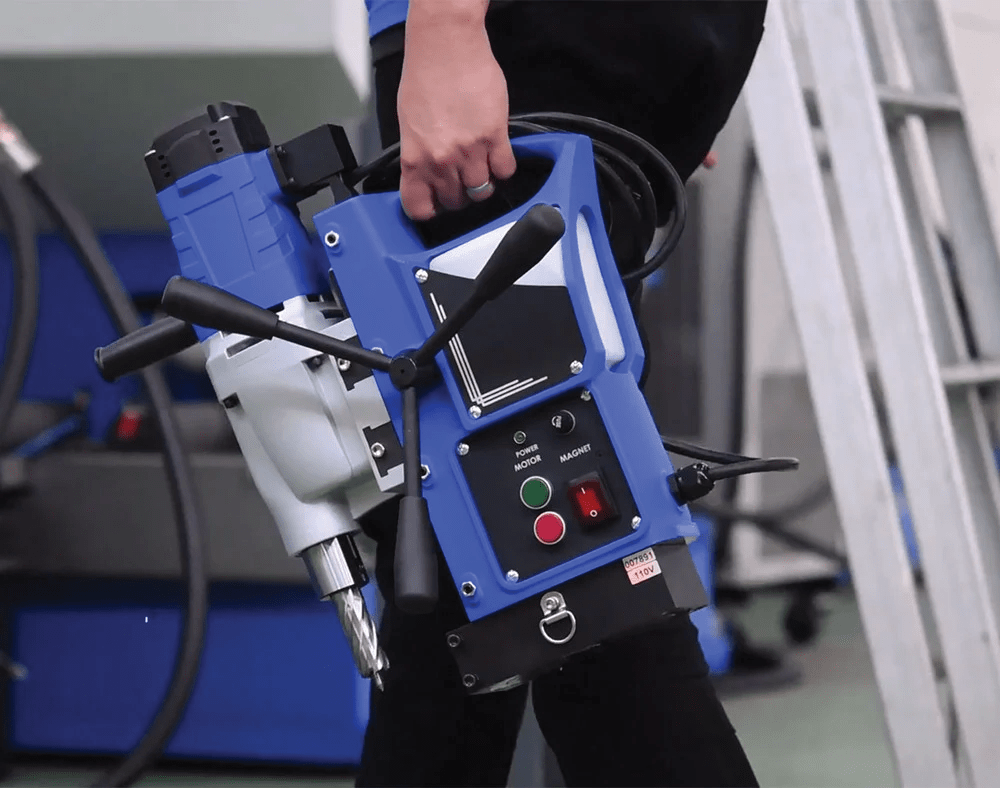

Imagine you have a $2,000 Magnetic Drill and a premium German annular cutter. You place the machine on a 4mm plate, activate the magnet, and the green light turns on. Confidently, you lower the lever, but as soon as the cutter tip engages the metal, the drill suddenly rotates, the cutter shatters, and the workpiece gets scratched. The operator might even get injured.

Technical managers of steel structure projects, machinery body manufacturing, or heavy automotive industries face a constant challenge: the need for precise and fast drilling on low-thickness plates (4 to 8mm). The Magnetic Drill, essential for this task, becomes unstable on these thin plates. The motor starts, the magnet activates, but as soon as the motor torque applies force to the annular cutter, the machine slips, rotates, or detaches from the work. This incident not only causes expensive cutters to break but, more importantly, poses a life risk to the operator and halts the production line. Often, the root of this problem is not a magnet failure, but a misunderstanding of magnetic force physics in metallurgy.

Technical Understanding of the Problem: Why is Magnet Adhesion Lost on Thin Plates?

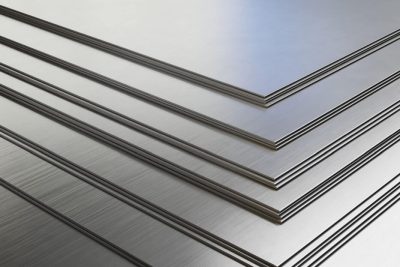

To solve a problem, you must understand its root cause. The main reason is the inability of the thin plate to fully transmit the magnetic flux generated by the machine’s coils. This phenomenon has two main physical reasons:

Reaching the Point of Magnetic Saturation

As mentioned before, the drill magnet creates a closed magnetic circuit. The magnetic flux must pass through the metal body and return to the other pole.

- Technical Analysis: Every ferromagnetic material (like standard steel) has a limited capacity to hold and transmit magnetic flux. When the plate thickness is low (e.g., under 8 to 10mm), the plate quickly becomes “saturated” with magnetic flux. In this state, a huge portion of the magnet’s force, instead of passing through the metal, escapes as “Leakage” into the surroundings (air).

- Operational Result: You are essentially wasting a large part of the machine’s force (which you paid for). This phenomenon causes even the strongest brands of magnets to perform poorly on thin plates.

Eddy Current and Hysteresis Losses

In electric magnetic drills (the most common type), the magnetic field oscillates with the power frequency (e.g., 50Hz). These oscillations inside the thin metal plate cause two destructive phenomena:

- Eddy Current: These excess currents convert electrical energy into heat. In thin plates, these losses can quickly cause the magnet to heat up, which itself is a reason for reduced adhesion force.

- Hysteresis Loss: This loss relates to the energy required to continuously reverse the magnetic poles in the metal (in every power cycle). This energy dissipation means a reduction in the net holding force, directly affecting magnet adhesion on thin plates.

Why is Magnet Adhesion Lost on Thin Plates?

Solution #1: Technique of Artificially Increasing Thickness with a Backing Plate

This technique is the global standard for solving the problem of magnet adhesion on thin plates and light profiles.

Introduction to the Backing Plate

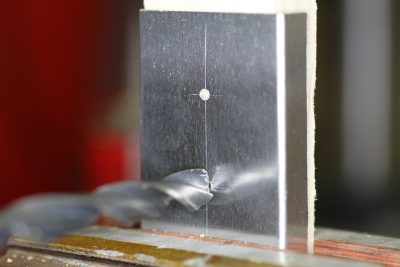

A backing plate (or auxiliary plate) is a simple but vital piece of high-quality flat steel with a thickness of at least 12 to 15mm. This plate acts as a “Magnetic Amplifier.”

| Technical Need | Backing Plate Solution |

| Thin Main Plate | The backing plate completes the magnetic circuit. |

| Air Gaps | By clamping, it eliminates all gaps between the magnet and the main plate. |

| Surface Irregularity | Creates a flat and ideal surface for the magnet base. |

Technical Protocol for Executing the Magnetic Sandwich

- Surface Preparation: All four contact surfaces (magnet base, top and bottom of the main plate, top of the backing plate) must be cleaned with a cloth and very fine sandpaper. Removing paint, rust, and fine chips is an absolute priority.

- Stacking: The backing plate (15mm) must be placed underneath the main plate (4mm).

- Eliminating Air Gaps: This is the most critical stage. The backing plate and the main plate must be tightly secured together using two powerful C-Clamps or toggle clamps at the four corners. The clamp pressure must guarantee that no microscopic gap remains.

- Drilling Execution: After activating the magnet, your adhesion force is now equivalent to adhesion on a thick plate, and you can proceed with drilling confidently.

Solution #2: Changing the Drill Type and Metallurgical Considerations

If, in special projects, access to the underside of the workpiece to place a backing plate is not possible, we must look into changing the machine type or material considerations:

Using Permanent Magnets

In cordless magnetic drills or some small models, strong permanent magnets (like Neodymium) are used.

- Advantage for Thin Plate: The permanent magnet has a more concentrated magnetic field in the near-field and shows better stability on thicknesses of about 4 to 5mm compared to electromagnets, as they do not have the Eddy Current loss problem.

- Warning: A permanent magnet does not release the machine even in case of a sudden power cut, but it still faces problems under 4mm.

Changing the Drill Type and Metallurgical Considerations

Adding Lateral Mechanical Force (Using Vacuum System)

For drilling on non-magnetic plates or plates thinner than 3mm, the entire magnet platform must be changed:

- Vacuum Magnetic Drill: These machines attach to the surface by creating a vacuum under the base. This is the only safe way for drilling on thin sheets (under 3mm) or non-ferrous metals (like Aluminum).

Selecting Cutter Alloy to Reduce Pressure

One of the main reasons for magnet slippage is excessive pressure and cutter vibration during cutting.

- TCT Annular Cutter: Using Tungsten Carbide Tipped (TCT) cutters instead of HSS, due to higher hardness and optimized cutting angle, enables smoother cutting with less feed pressure. Consequently, the sudden motor torque that can cause magnet detachment is reduced.

Quick Troubleshooting Checklist for Magnet Adhesion on Thin Plates

If you still have slippage problems despite observing sufficient thickness, follow this checklist:

| No. | Factor | Cause | Quick Solution |

| 1 | Surface Roughness | Fine chips, rust, or thick paint under the magnet. | Clean the magnet base and work surface with a wire brush and solvent. |

| 2 | Cable & Voltage | Power network voltage drop (under 220V) or worn cable. | Connect the machine to a strong mains power. Check input voltage with a multimeter. |

| 3 | Metal Type | Working on Cast Iron, 300 Series Stainless Steel, or High Carbon alloys. | For Stainless, consider Permanent Magnet or Vacuum. For Cast Iron, smooth the surface completely. |

| 4 | Magnet Temp | Continuous operation and overheating of the magnet. | Give the machine a rest. High magnet temperature directly reduces adhesion. |

| 5 | Insufficient Thickness | Not using a backing plate. | Refer to Section 2 and execute the sandwich technique. |

Frequently Asked Questions (FAQ)

- Is using temporary magnetic glues effective for increasing adhesion on thin plates? Yes, in some specialized industries, resins or thin glues based on ferromagnetic powder are used to fill microscopic air gaps between the magnet and metal. This method can compensate for 1 to 2mm of thickness deficiency, but the primary method is using a backing plate.

- Why do larger-sized magnets perform weaker on thin plates? Larger magnets (with 2000+ kg force) generate much more magnetic flux. When this flux enters a thin plate, a higher percentage of it leaks (because the plate capacity is saturated). In fact, absolute force losses in larger magnets on thin plates are significantly higher. For thin plates, it is better to use magnetic drills with a small base and balanced force.

- What is the difference in adhesion when working on ST37 Steel vs. Cast Iron? ST37 (Structural Mild Steel) has excellent ferromagnetic properties and is the best material for magnet attraction. Cast Iron has a granular and non-uniform structure. This structure causes the magnetic flux to be conducted mostly in points rather than uniformly; consequently, adhesion on cast iron is always less than on mild steel.

Final Conclusion

Success in drilling thin plates is achieved not by buying a more expensive magnetic drill, but by correctly understanding magnet physics and strictly executing engineering protocols. The problem of magnet adhesion on thin plates is a technical problem with a technical solution: either provide the underlying thickness with a backing plate, or utilize special equipment (like vacuum bases or permanent magnets).

Operator safety and maintaining your equipment’s health is our priority. At Rahmani Magnetic Drill Store, as a specialized reference for sales and repair of magnetic drills, we are ready to offer the best solution for light plate drilling challenges in your project (from structures to shipbuilding) via free consultation. For guaranteeing 100% safety and precision, contact our sales experts right now.