Magnetic Drill Repair: Common Failures, Causes, and Effective Solutions

Magnetic Drill Repair: Common Failures, Causes, and Effective Solutions

Magnetic drills are essential tools for industrial applications, delivering high precision and efficiency. However, even the best machines can experience malfunctions over time. This comprehensive guide covers common magnetic drill failures, their root causes, and effective repair solutions. For industry professionals seeking reliable service, Clinic Abzar—the specialist repair center for magnetic drills—offers expert assistance and genuine replacement parts.

Introduction

Magnetic drills, renowned for their ability to securely attach to metal surfaces via powerful electromagnets, provide precision drilling in heavy industrial tasks. Despite their robust design, these tools can suffer from wear and tear. Understanding the common issues and learning proper maintenance techniques is crucial for ensuring long-term performance

Common Failures and Their Causes

Teeth Breakage

- Cause:

- Excessive applied pressure or an improper drilling angle

- Operating at too high a rotational speed

- Overloading beyond the machine’s capacity

- Solution:

- Replace broken cutting teeth with genuine components

- Optimize drill speed and ensure operators use moderate, steady pressure

Dulling of Cutting Edges

- Cause:

- Prolonged use without maintenance

- Insufficient lubrication leading to increased friction

- Inappropriate cutter selection for the material

- Solution:

- Regularly inspect and sharpen cutting edges; replace if necessary

- Apply high-quality lubricants or coolants during operation

Magnetic Clamping Failure

- Cause:

- Worn or damaged electromagnetic components

- Surface contamination (e.g., rust, oil) preventing proper adhesion

- Inadequate cleaning and maintenance of the magnetic system

- Solution:

- Clean the work surface and inspect the magnet for wear

- Replace degraded electromagnetic coils to restore clamping force

Motor Malfunction

- Cause:

- Overheating due to dust accumulation or poor cooling

- Electrical faults such as worn wiring or loose connections

- Lack of routine maintenance leading to component degradation

- Solution:

- Clean the motor and cooling system regularly

- Repair or replace faulty wiring and ensure proper lubrication of moving parts

Gearbox Issues

- Cause:

- Excessive load causing gear wear or misalignment

- Insufficient or low-quality lubrication

- Extended operation without scheduled maintenance

- Solution:

- Replace worn gears and realign gearbox components

- Establish a regular maintenance schedule for lubrication checks

Rust and Corrosion

- Cause:

- Failure to clean the drill after use, leading to moisture retention

- Exposure to corrosive environments without protective coatings

- Solution:

- Thoroughly clean and dry the magnetic drill after each use

- Apply anti-corrosion treatments or coatings, and store in a controlled environment

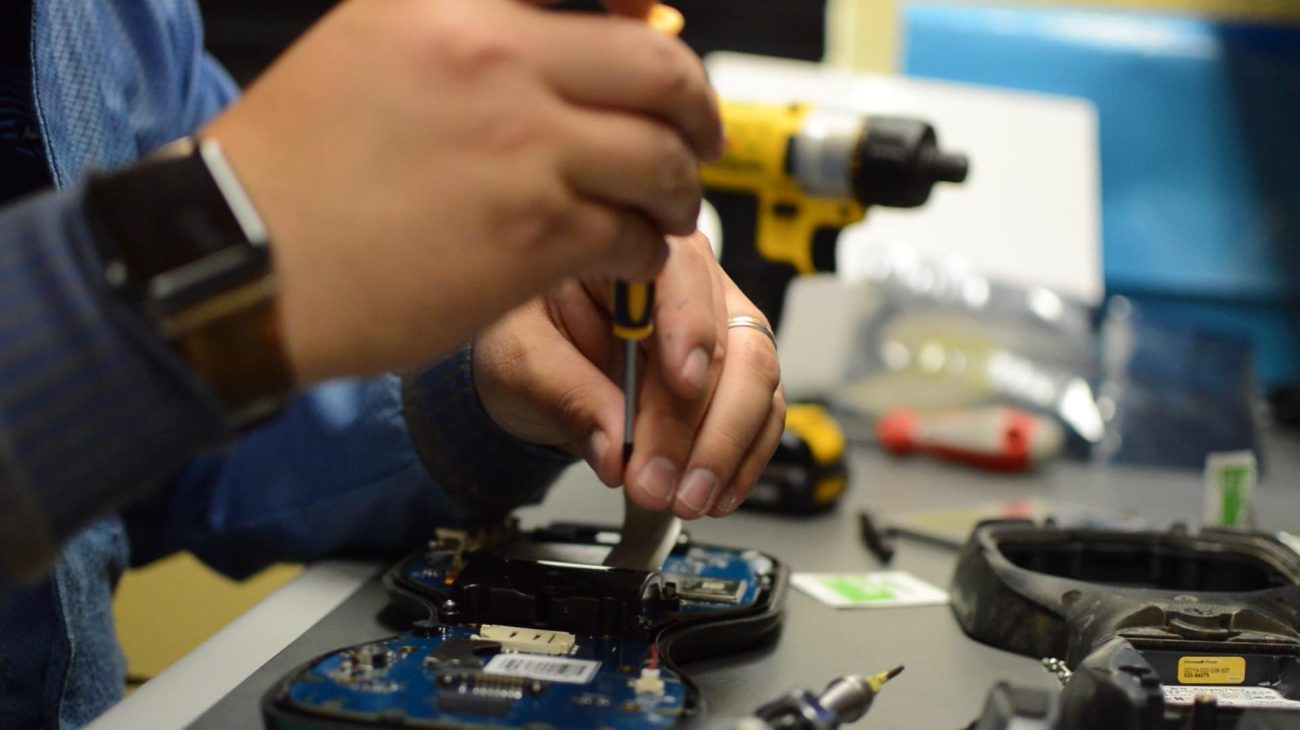

Electrical Component Failures

- Cause:

- Faulty soldering, worn connectors, or internal short circuits

- Voltage fluctuations or harsh operating conditions

- Solution:

- Inspect and replace damaged wiring and electrical components

- Use surge protectors and operate within recommended electrical parameters

Preventative Maintenance and Repair Best Practices

- Regular Inspections: Schedule routine checks to catch early signs of wear or malfunction.

- Operator Training: Ensure operators are trained on proper usage to prevent overloading and misuse.

- Quality Lubrication: Use manufacturer-recommended lubricants to reduce friction and extend component life.

- Environmental Control: Store equipment in a dry, controlled environment to avoid rust and corrosion.

- Timely Repairs: Address issues immediately to prevent further damage and minimize downtime.

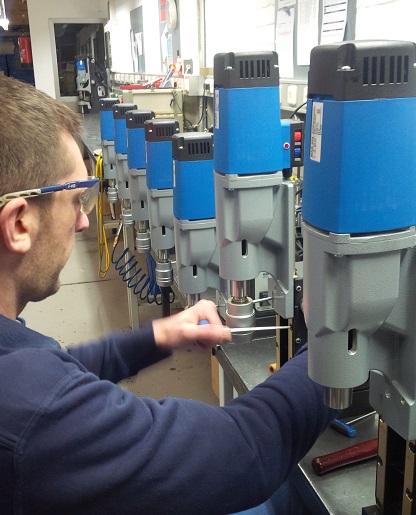

Why Choose Clinic Abzar for Magnetic Drill Repair

Clinic Abzar is a leading specialist repair center dedicated to magnetic drills. Our service advantages include:

- Expert Technicians: Our team consists of highly skilled professionals with in-depth knowledge of magnetic drill mechanics.

- Comprehensive Services: We handle everything from routine maintenance to major repairs, ensuring your equipment operates at peak performance.

- Genuine Replacement Parts: We only use authentic components to guarantee long-lasting repairs.

- Rapid Turnaround: Our efficient service minimizes downtime, keeping your operations running smoothly.

- Customer-Centric Approach: We tailor our repair solutions to meet the specific needs of industrial professionals.

Conclusion

Magnetic drills are critical assets in industrial applications, but their performance hinges on proper maintenance and timely repairs. By understanding common failure modes—such as teeth breakage, dulling, magnetic clamping issues, motor and gearbox malfunctions, rust, and electrical problems—professionals can implement effective repair strategies and preventative measures.

For those seeking reliable, expert magnetic drill repair, Clinic Abzar offers specialized services, genuine parts, and comprehensive support to ensure your equipment remains at its best. Trust Clinic Abzar for all your magnetic drill repair needs and to maintain uninterrupted productivity.