Guide to Choosing Annular Cutter Size for Metal Projects

Guide to Choosing Annular Cutter Size for Metal Projects

Introduction: Why Is Choosing the Right Annular Cutter Size Important?

One of the most significant challenges when drilling metals is the selection of the correct annular cutter size. Although it may seem simple, in practice, it directly affects work quality, execution speed, project cost, and even the lifespan of the magnetic drill machine.

If the wrong size is chosen, the hole may end up larger or smaller than required, the cutter may be subjected to excessive pressure and break prematurely, or even the magnetic drill motor may get damaged.

Many beginners assume that any cutter size can meet their needs. However, choosing the annular cutter size is an engineering process that must be based on specific parameters: the required diameter, drilling depth, material type, and even the type of machine used.

The goal of this article is to explain step-by-step how to choose the correct annular cutter size. In addition to introducing the influencing factors, we will also provide a practical reference table that users can easily consult for different projects.

Understanding the Main Parameters in Choosing the Annular Cutter Size

To choose the right annular cutter size, you must consider several key parameters. These factors help you select a cutter that fits your project requirements and prevent issues such as tool breakage, reduced drilling accuracy, or wasted costs.

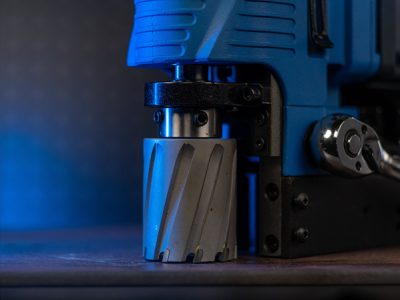

Required Hole Diameter

The first and most important factor is the diameter of the hole that must be made in the metal piece. Annular cutters are produced in a wide range of sizes, from 12 mm up to over 100 mm. Selecting the precise diameter is essential: if the hole is too small, you will have to repeat the drilling process; if it is too large, the workpiece may become unusable. Always determine the cutter diameter carefully according to the blueprint or project requirements.

Drilling Depth

Annular cutters are usually manufactured in different lengths, for example, 30 mm, 55 mm, and even 110 mm. Choosing the wrong length can create two problems:

• If the cutter is too short, it will not complete the hole.

• If it is too long, it can cause higher vibration and reduced precision.

Therefore, the cutter length must exactly match the thickness of the metal piece.Material Type (Metal to Be Drilled)

The selection of the annular cutter size also depends on the type of metal being drilled. For example, drilling thick or hard steel with very large diameters can overload the tool and the drill motor. In contrast, for aluminum or softer metals, larger diameters can be used without issues.

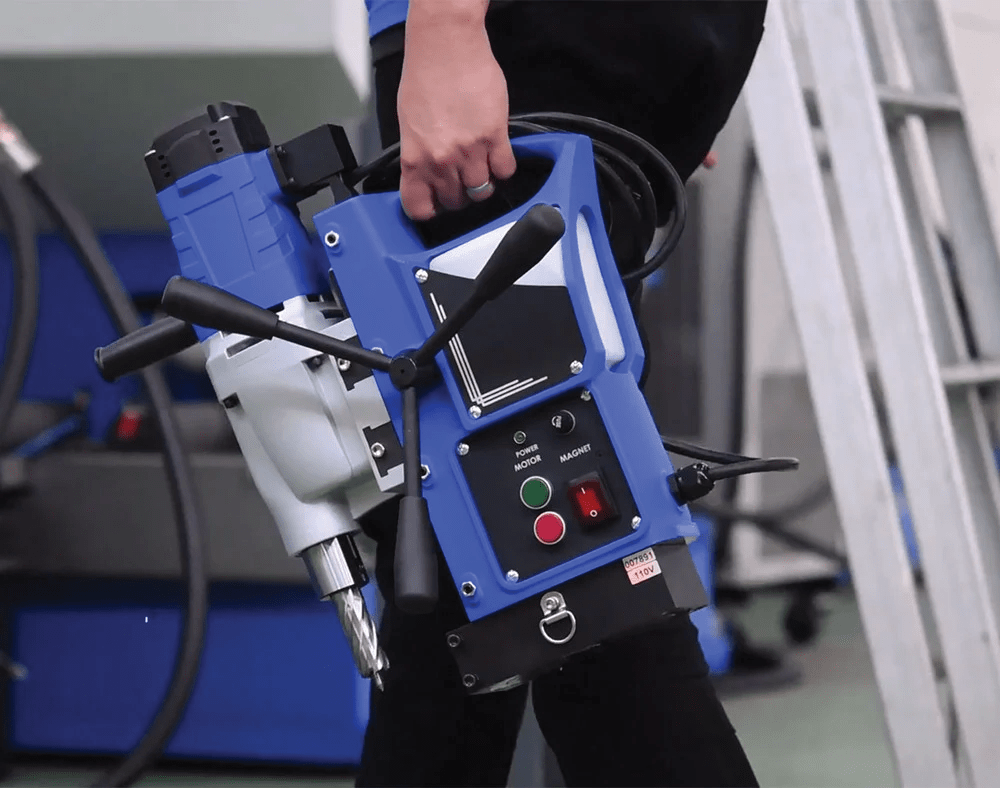

Machine Type (Magnetic or Bench Drill)

Ensure that your machine can support the chosen size. Each magnetic drill or bench drill has specific limits for hole diameter and depth. For instance, a lightweight magnetic drill may handle cutters up to 35 mm, while heavy industrial models can support cutters up to 80 mm or even 100 mm.

The Main Parameters in Choosing the Annular Cutter Size

Recommended Annular Cutter Diameter and Depth for Different Materials

One of the best ways to understand how to choose the correct annular cutter size is to use a reference table. This table helps you select the proper size based on the thickness of the workpiece and the type of material.

| Material Type | Workpiece Thickness | Recommended Cutter Diameter | Recommended Cutter Depth |

| Structural Steel | 5–20 mm | 14–35 mm | 30 mm |

| Structural Steel | 20–40 mm | 18–45 mm | 55 mm |

| Stainless Steel | 5–15 mm | 12–30 mm | 30 mm |

| Stainless Steel | 20–30 mm | 14–35 mm | 55 mm |

| Aluminum & Soft Metals | 5–20 mm | 20–30 mm | 30 mm |

| Aluminum & Soft Metals | 20–50 mm | 20–35 mm | 55 mm |

| Cast Iron & Thick Sections | 20–30 mm | 30–80 mm | 80–110 mm |

| Industrial Heavy Plates | 60 mm+ | 35–90 mm | 110 mm |

Important Note:

This table is only a practical guide. The final selection of the annular cutter size should always be made considering the machine’s power, cooling conditions, and cutter type (HSS or TCT). For example, when drilling stainless steel, TCT cutters are recommended since HSS ones tend to dull quickly.

Why Is This Table Useful?

Many users choose the cutter size based solely on the required hole diameter without considering the thickness or type of material. This mistake can cause excessive stress on both the machine and the cutter. By using such reference tables, you can make a smarter choice and avoid common problems such as tool breakage or overheating.

Common Mistakes in Choosing the Annular Cutter Size

Many users, when buying or using an annular cutter, focus only on the hole diameter and ignore other important factors. The result is that the cutter breaks quickly, the machine is overloaded, or the drilling becomes inaccurate and inconsistent. Below are some of the most common mistakes:

Ignoring the Workpiece Thickness

A common mistake is when users think only about the hole diameter but do not choose the cutter length according to the metal’s thickness. For example, using a 30 mm cutter on a 40 mm steel plate leaves the hole unfinished, forcing you to redo the operation with a longer cutter.

Using a Cutter Larger Than the Machine’s Capacity

Every magnetic drill or bench drill has its own limits. Installing a cutter with a diameter larger than what the machine supports puts excessive pressure on the motor. This not only damages the drill but also increases the risk of the cutter getting stuck or breaking.

Choosing Cheap, Low-Quality Cutters

Some users choose unbranded, low-cost cutters to save money. The problem is that even if the annular cutter size is correct, such tools wear out quickly and jam in thick materials. This results in higher costs for replacements in the long run.

Ignoring the Material Type

A cutter suitable for mild steel may not work properly on stainless steel. When choosing both the size and type of cutter, the workpiece material must always be considered. For example, TCT cutters with the proper diameter are ideal for stainless steel.

Neglecting Cooling Conditions

Even if the right size is selected, improper cooling can cause the cutter edges to overheat and break. This issue is particularly common when working with larger diameters.

Common Mistakes in Choosing the Annular Cutter Size

Professional Tips for Increasing Accuracy in Choosing the Annular Cutter Size

Choosing the right annular cutter size involves more than just tables and technical specifications. Professional users always consider a few key points to ensure maximum performance from the selected cutter in their projects.

Pay Attention to the Drill Speed

Each cutter size has its optimal rotational speed. Generally, the larger the cutter diameter, the lower the rotation speed should be. For instance, an 18 mm cutter can rotate at a higher speed, while a 50 mm cutter requires slower rotation and steady pressure. If your drill does not have speed control, it is better to use smaller diameters to prevent damage to both the cutter and motor.

Match the Cutter with the Machine Type

Not all machines can support all sizes. Lightweight magnetic drills are typically designed for cutters up to 35 mm, while heavy-duty industrial models can handle cutters ranging from 60 mm to 120 mm. Always check the chuck capacity and motor power before choosing the cutter size.

Use Proper Cooling

As the cutter diameter increases, so does friction and heat. Choosing a large cutter without proper cooling is a serious mistake. Using coolant oil or an integrated cooling tank helps resist heat buildup and extends the cutter’s lifespan several times over.

Observe Tolerances in Precision Projects

In high-precision projects such as industrial structures or specialized equipment, drilling accuracy is critical. In such cases, the cutter size should be slightly smaller than the final required hole diameter, allowing finishing processes like reaming to achieve perfect precision. This reduces error and ensures a more professional result.

Consult Specialists

If you are unsure about selecting the cutter size, the best solution is to consult experts. Stores like Matesara have extensive experience with different projects and annular cutter brands and can help you choose a size that fits both your project and machine.

Professional Tips for Increasing Accuracy in Choosing the Annular Cutter Size

Conclusion: Selecting the Annular Cutter Size with Matesara’s Guidance

Choosing the right annular cutter size not only guarantees drilling quality but also extends cutter life, reduces strain on the machine, and minimizes extra project costs. As we’ve seen, factors such as hole diameter and depth, material type, machine power, and cooling conditions all play key roles in this decision.

By using reference tables and following professional tips, you can make the best possible choice. However, if you are still uncertain, expert advice is invaluable. Matesara, as one of the main suppliers of HSS and TCT annular cutters, offers not only a wide product range but also free technical consultation.

That means you get the right tool and ensure your chosen cutter size perfectly matches your project and machine.

If you’re looking for a smart and reliable purchase, trust Matesara, where product variety, authenticity, and professional support come together to create a truly different buying experience.