Difference Between Annular and Twist Drill Bits in Metal Drilling Accuracy and Performance

Difference Between Annular and Twist Drill Bits in Metal Drilling Accuracy and Performance

Introduction

In metal drilling, the tool you choose has a direct impact on accuracy, performance, and tool life. Many users assume that any drill bit can handle any metal, yet the reality is different. The geometry, cutting angle, and structure of each bit are designed for specific tasks. This is why understanding the annular vs twist drill difference is essential before starting a metalworking project. Annular cutters, used in magnetic drills and heavy industrial work, are built for precise cuts in thick materials. Twist drills perform better in continuous drilling with smaller diameters and thinner metals. Knowing these differences improves accuracy and prevents burning, chipping, and tool breakage. In the following sections, we review the structure and applications of both types to identify which option performs better in real workshop conditions.

Introduction to Annular Cutters

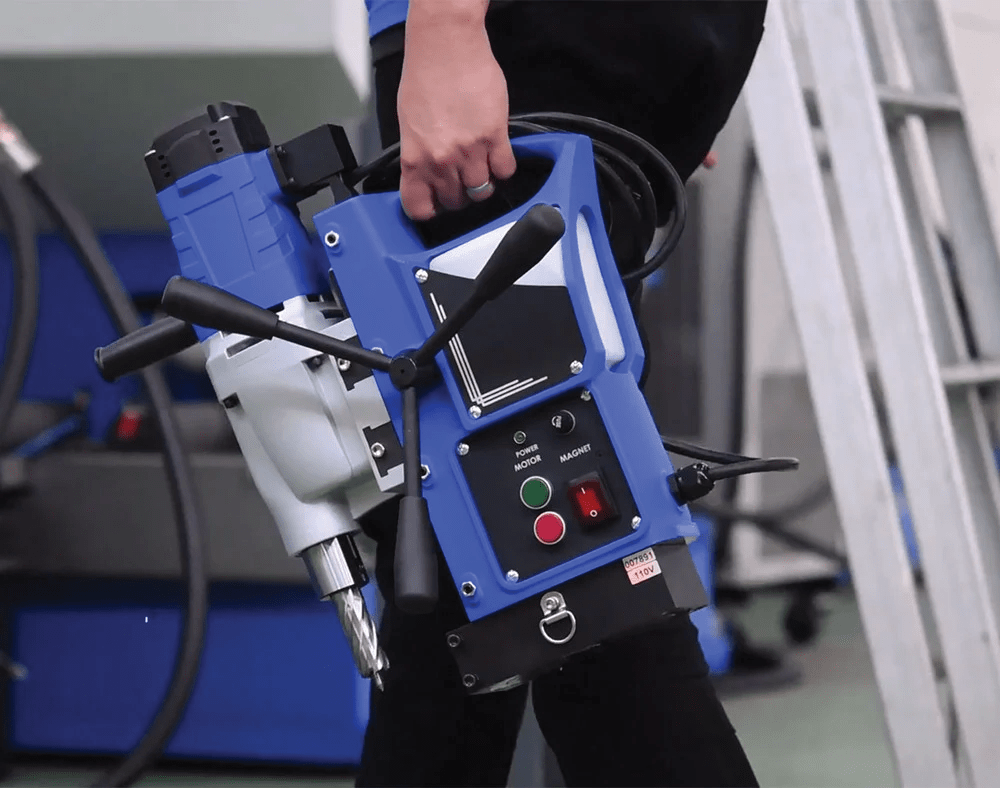

Understanding annular cutters is essential when comparing the annular vs twist drill difference. Unlike twist drills that remove all material inside the hole, annular cutters only cut the perimeter and eject a clean cylindrical core. This design reduces load on the motor and increases drilling speed. Their angled cutting teeth create smooth cuts across different metal thicknesses. Professional models use HSS or heat-resistant carbide teeth to prevent burning or dulling during heavy contact with metal. German brands such as Grollen, Kolsch Stahl, and Wikinger use precision grinding technology to achieve fast cutting and smooth hole surfaces. In contrast, low-quality cutters with incorrect tooth angles often cause vibration, noise, and edge chipping. Choosing a high-quality annular cutter, especially for magnetic drills and industrial machinery, improves accuracy and reduces long-term tool maintenance costs.

Introduction to Annular Cutters

Introduction and Function of Twist Drills

The twist drill is one of the oldest and most widely used tools in metalworking. To understand the annular vs twist drill difference, it is important to know how a twist drill works. This tool removes all material inside the hole, which makes it ideal for small to medium diameters. The spiral angle on the body helps lift chips upward, keeping the cutting path clean. However, in thicker materials, this feature becomes a weakness. Chip buildup inside the flutes increases heat, friction, and reduces accuracy. Most twist drills are made from HSS or HSS-Co, which offer good heat resistance, but they still require coolant when drilling stainless steel or other hard alloys. In general workshops and light production lines, twist drills are popular due to their lower cost and easy availability. Still, compared with annular cutters, they offer lower drilling accuracy and place more load on the machine motor. For thick steel sections or precision work, standard twist drills often cause oval holes or chipping at the tip. Knowing these limitations helps professionals choose the right tool for industrial projects.

Introduction and Function of Twist Drills

Comparing Cutting Geometry Between Annular Cutters and Twist Drills

At first glance, annular cutters and twist drills may appear similar, yet a closer look at their geometry and force transfer shows the real difference. This comparison is essential when evaluating the annular vs twist drill performance. Annular cutters use a cylindrical wall with sharp teeth that cut only the perimeter of the hole. Twist drills, however, remove material from the center outward. This geometric contrast has a direct effect on drilling accuracy. Annular cutters typically use a 10–15° rake angle to distribute cutting force evenly across all teeth. Twist drills rely on a 25–30° spiral angle to move chips upward. In thick materials, this often leads to chip packing, higher heat, and reduced accuracy. Annular cutters maintain stability even in metals thicker than 40 mm.

Cutting Angle and Force Distribution in Annular Cutters

The cutting attack angle and tooth engagement in annular cutters distribute force symmetrically around the tool axis. This reduces vibration and improves stability, especially in magnetic drills. In professional models from FE Powertools, the outer teeth are ground in stages to reduce load per revolution and ensure smooth chip evacuation. This design results in a clean, burr-free hole with high dimensional accuracy.

Spiral Angle and Chip Behavior in Twist Drills

The higher spiral angle in twist drills improves chip evacuation, but it also concentrates force on the drill point. When drilling hard metals like stainless steel, this concentrated pressure produces heat and may cause discoloration, burning, or tip breakage without coolant. For this reason, twist drills are not recommended for thick industrial steel sections. However, for thin sheets or softer metals, twist drills remain a fast and economical option thanks to their lower cost and higher drilling speed.

Accuracy Differences Between Annular Cutters and Twist Drills in Metal Drilling

When precision matters, understanding the annular vs twist drill cutting behavior becomes crucial. In real workshop conditions, annular cutters achieve higher accuracy thanks to their tooth-based design. They cut only the perimeter of the hole, distributing force across multiple teeth. This produces cleaner edges and a more stable cut. Twist drills, however, focus pressure on the drill tip. This often causes the bit to slip or wander at the start, which increases the risk of an oval hole. This technical contrast represents the main accuracy difference between an annular cutter and a twist drill, and it is exactly why annular cutters dominate heavy industrial applications.

Magnetic Drill Stability and Its Effect on Precision

In magnetic drills, where axial stability is essential, annular cutters deliver superior alignment. Their cylindrical structure and peripheral cutting reduce vibration and limit kickback. Brands like Kolsch Stahl use optimized tooth geometry and precision-ground shanks to minimize hole deviation. Compared to twist drills, which typically allow more tolerance, annular cutters maintain higher repeatability and are ideal for frequent, precision-critical operations.

Twist Drill Behavior Under Workshop Conditions

Tests on thick steel plates show that twist drills lose accuracy as friction and heat increase during deep drilling. This becomes more evident in serial drilling or when using bench-type machines. For this reason, even experienced operators often combine both tools: a twist drill is first used to create a pilot hole, followed by an annular cutter to finish the hole with perfect roundness and smooth edges. This method reduces vibration, speeds up the process, and enhances final accuracy.

Differences Between Annular Cutters and Twist Drills in Metal Drilling

Speed and Tool Life Differences Between Annular Cutters and Twist Drills

When comparing the cutting performance of annular vs twist drill designs, speed and tool life become decisive factors. Tests on mild steel and stainless steel show a clear performance gap. Annular cutters, thanks to their tooth-based cutting geometry and the absence of full-core material removal, apply far less load to the motor. This allows significantly higher cutting speeds. For example, during a 35 mm drilling test, annular cutters completed the cut up to 40 percent faster than twist drills. In large-scale applications, such as steel structure fabrication or industrial frame assembly, this difference translates into major savings in time, energy, and operational cost. Twist drills, on the other hand, must remove the entire cross-section of the metal, which demands high torque and increases cutting resistance. As a result, more heat accumulates at the drill tip, reducing tool life.

Long-Term Durability of Each Tool Type

Durability tests on German brands such as Grollen and Wikinger show that carbide-tipped annular cutters last up to three times longer than HSS twist drills. This durability advantage comes from the way each tool contacts the material. Annular cutters engage the metal through multiple point-to-point contacts, whereas twist drills experience continuous surface contact that accelerates wear. In advanced FE Powertools models, an internal cooling channel helps remove chips efficiently and prevents tooth overheating. This innovation dramatically increases tool longevity under heavy workshop conditions, making annular cutters the superior choice for demanding projects.

Choosing Between Annular Cutters and Twist Drills Based on Project Type and Metal Thickness

Choosing between annular vs twist drill tools depends not only on price or availability, but also on project type, material thickness, and metal hardness. To understand the real difference between annular and twist drills, it is essential to know the ideal working conditions for each tool. Annular cutters perform significantly better on materials thicker than 10 mm, because their tooth-based geometry reduces cutting force while increasing speed. For this reason, they are the preferred choice in steel-structure fabrication, bridge construction, and heavy industrial equipment manufacturing. Meanwhile, twist drills are more suitable for lighter, precision-focused applications such as electrical panels, aluminum structures, or thin sheet-metal components.

Matching the Tool to Metal Type

On soft metals such as aluminum or copper, twist drills deliver excellent performance due to fast chip evacuation and reduced risk of jamming. However, on harder materials like stainless steel or cast iron, a carbide-tipped annular cutter performs far better. Brands like Kolsch Stahl use advanced tooth geometry and TiN coating to ensure that the cutter maintains speed and resists chipping even under continuous contact with hard alloys. This design preserves long-term accuracy and minimizes the need for re-sharpening.

Role of the Machine in Choosing the Right Drill

The machine used also influences the choice between annular vs twist drill systems. Magnetic drills and industrial drill presses are engineered specifically for annular cutters because their magnetic base stabilizes the tool and eliminates vibration. Conversely, handheld or portable drills—commonly used in maintenance or light-duty work—perform better with twist drills. Understanding this difference not only improves drilling accuracy and speed but also prevents damage to the tool and extends the lifespan of the machine.

Choosing Between Annular Cutters and Twist Drills Based on Metal Thickness

Cost, Maintenance, and Economic Efficiency: Annular vs Twist Drill

When evaluating industrial tools, factors such as price, maintenance cost, and long-term value play a major role. At first glance, annular cutters may seem more expensive than twist drills, but when you consider durability, cutting speed, and final accuracy, the real difference clearly favors annular cutters. In large-volume operations, using annular cutters can reduce total project cost by up to 30 percent, because the cutting time is shorter and the load on the magnetic drill motor is significantly lower. On the other hand, twist drills, despite their lower initial price, tend to dull quickly under heavy-duty use and require frequent sharpening or replacement, which increases long-term maintenance costs.

Durability and Re-Sharpening

High-quality annular cutters, especially carbide-tipped models from brands like Grollen and Wikinger, can be re-sharpened multiple times without losing cutting precision. This extends tool life dramatically. Twist drills, however, lose their original geometry during sharpening due to their continuous flute design and chisel-point tip. As a result, many workshops replace twist drills after only a few uses because they can no longer maintain accurate hole geometry.

Economic Advantage in Industrial Operations

In large industrial projects such as steel-structure fabrication, oil and gas facilities, or port construction, downtime caused by tool failure can lead to significant financial loss. This is where the annular vs twist drill difference becomes critical. Annular cutters maintain stable performance during repetitive cuts due to better cooling and more efficient force distribution. Consequently, although the initial cost is higher, the long-term economic return is substantially greater.

Conclusion: Which Tool Offers Better Performance?

A technical and practical comparison shows that the annular vs twist drill difference goes far beyond appearance or price. Annular cutters, with their tooth-based cutting structure, offer higher speed, greater accuracy, and longer tool life, making them the ideal choice for heavy-duty industrial work, thick steel drilling, and magnetic drill operations. Twist drills, on the other hand, perform better in lighter applications and thinner materials, but when used on hard metals or in deep drilling, they tend to lose accuracy, generate excessive heat, and wear out quickly.

If your goal is to achieve cleaner cuts, reduce machine stress, increase tool life, and save both time and cost, choosing an annular cutter from reputable brands such as Grollen, Kolsch Stahl, Wikinger, or FE Powertools is the most reliable option.

At MateSara, you can find a complete range of high-quality industrial annular cutters designed for various metalworking and structural applications. Before choosing a tool, always consider the material type, metal thickness, and the machine you are using to ensure the best performance and longest tool life.