Complete Guide to Industrial Drill Gearbox Maintenance and Repair

Complete Guide to Industrial Drill Gearbox Maintenance and Repair

Introduction

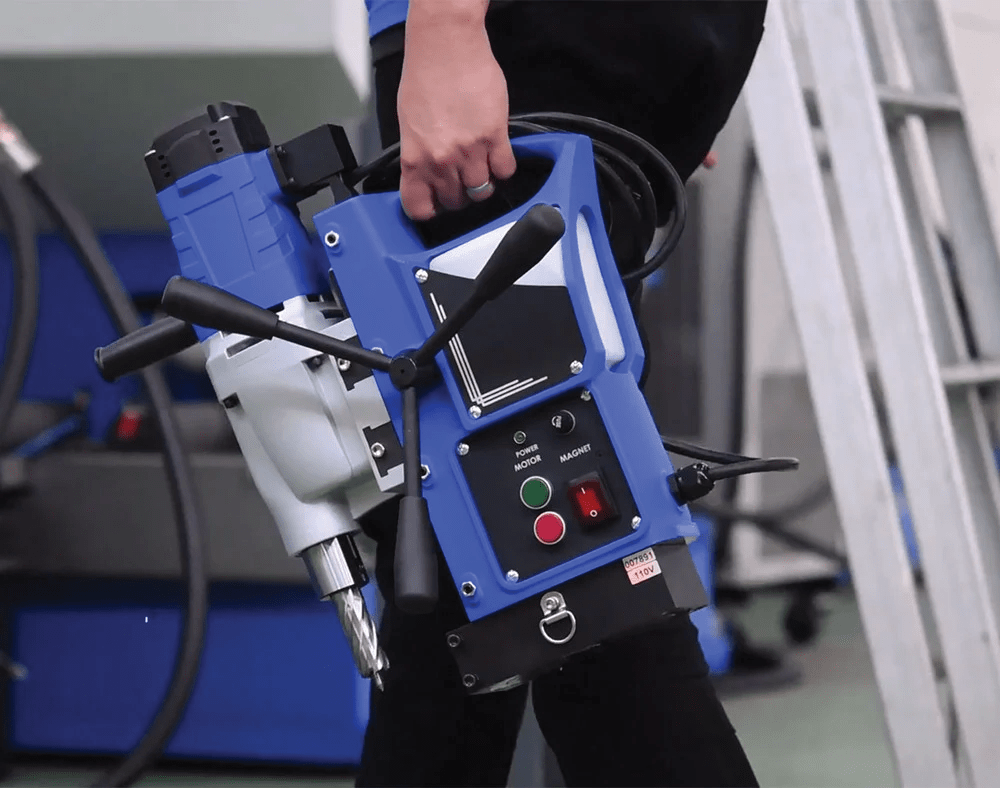

Inside many industrial tools, especially heavy-duty drills, resides a crucial yet often hidden component: the gearbox. This power-transmission system is responsible for converting and controlling the motor’s torque and speed, and without it functioning properly, no drill can perform as needed. Since the gearbox is constantly subjected to mechanical forces and high temperatures, it is also one of the parts that experiences the most wear.

From unusual noises to shaft jamming or reduced output power, the early signs of gearbox failure can disrupt machine performance and even damage other internal parts. Although many users quickly consider replacing the entire device, in most cases, a proper industrial drill gearbox repair not only resolves the problem but can also significantly extend the drill’s service life.

>In this article, we provide a complete overview of industrial drill gearbox structure, the main causes of failure, professional repair methods, and essential preventive maintenance tips. The goal is to help technicians and professional users better understand how this component works, avoid costly breakdowns, and maintain the long-term performance of their tools.

Structure and Function of Gearboxes in Industrial Drills

The Role of the Gearbox in Industrial Tools

The gearbox in an industrial drill act as the mechanical brain of the machine. Its primary function is to convert the motor’s high rotational speed into lower but stronger torque, which is essential for turning the cutter against the resistance of the material. Depending on the drill type and application, gearboxes may be single-speed or multi-speed, mechanical or electromechanical.

>This unit is typically enclosed in a steel or aluminum housing and consists of multiple gears, a drive shaft, bearings, washers, and, in some models, a mechanical or magnetic clutch system. The precision of gear design and tooth engagement has a direct impact on smooth rotation and efficient power transmission, factors that directly influence the need for proper industrial drill gearbox repair when issues arise.

The Role of the Gearbox in Industrial Tools

Types of Gearboxes in Drills

Common gearboxes used in industrial drills generally fall into three main categories:

- Single-speed gearboxes: The simplest type, suitable for general applications with stable load conditions.

- Two- or multi-speed gearboxes: Designed for users who require more precise control over speed and torque. These are commonly found in magnetic drills, core drills, and drill presses.

- Gearboxes with safety clutches: Present in advanced models to protect both the user and the machine in case the cutter locks or jams.

Types of Gearboxes in Drills

Importance of Lubrication and Cooling

Proper lubrication is essential for optimal gearbox performance. In most industrial models, the gearbox cavity is filled with grease or gear oil to reduce friction, prevent gear wear, and dissipate heat. Under heavy or continuous loads, insufficient cooling can lead to gear tooth deformation or shaft breakage, making timely maintenance and preventive inspection crucial.

Common Signs of Gearbox Failure in Industrial Drills

Unusual or High-Pitched Noises

One of the earliest indicators of gearbox problems is the presence of unusual sounds when the drill is running. These noises may include clicking, continuous squealing, grinding sounds, or intermittent knocking. The primary causes are typically worn gears, loose shafts, or damage to internal bearings.

>Hearing such noises, especially in drills that previously operated smoothly and quietly, is a serious warning sign that the machine should be stopped immediately and inspected. Continuing operation in this state can lead to severe damage and significantly higher industrial drill gearbox repair costs.

Loss of Power or Sudden Shutdown

If the drill lacks sufficient power at startup or stops unexpectedly during drilling, the gearbox is likely malfunctioning. This issue often occurs when power transmission from the motor to the shaft is disrupted, or when the gear teeth are broken or heavily worn.

>If the problem is accompanied by a burning smell or excessive heat, the cause may be burnt grease, damaged oil seals, or lubrication failure, all of which require urgent repair to prevent further damage.

Oil or Grease Leakage from the Gearbox Housing

Leaking grease or oil along the gearbox edges indicates failure of internal seals or gaskets. If not detected early, lubrication will progressively decrease, eventually leading to gear seizure or complete gearbox failure. Regular visual inspection of the gearbox housing helps detect leaks before they cause serious mechanical issues.

Excessive Vibration During Operation

A noticeable increase in vibration during drilling may result from misaligned gears, damaged bearings, or an unbalanced shaft. If the vibration continues, the gearbox housing may crack, or the entire gearbox assembly may fail. Early diagnosis and maintenance are essential to avoid major mechanical breakdowns.

Common Signs of Gearbox Failure in Industrial Drills

Professional Methods for Disassembling, Inspecting, and Repairing Industrial Drill Gearboxes

Safe Preparation and Gearbox Disassembly

Before performing any repair, the machine must be completely disconnected from its power source. If the drill operates on hydraulic or pneumatic power, all connections must be safely released and the system depressurized. The device should then be placed on a stable, clean workbench with proper lighting.

Opening the gearbox housing is usually done with a screwdriver or an Allen wrench. During this stage, utmost care is needed to prevent internal components, especially washers, bearings, and retaining clips, from shifting or getting lost. It is recommended to document each step with photos or video so the assembly sequence can be accurately followed during reinstallation as part of a proper industrial drill gearbox repair procedure.

Inspecting Internal Components

Once fully opened, the first step is a visual inspection of all internal parts. Worn gear teeth, cracked gears, corroded shafts, or discolored grease are all indicators confirming gearbox malfunction. Any gear with sharp, chipped, or broken teeth must be replaced immediately.

Bearings and shafts should also be checked for excessive play, cracks, or rough noise. In many cases, bearing failures can be identified simply by manually rotating them and listening for dry or grinding sounds.

Cleaning, Parts Replacement, and Re-Lubrication

After identifying defective components, they must be replaced with original, compatible parts. When selecting new grease or gear oil, the manufacturer’s recommendations must be followed. Some gearboxes operate with heavy industrial grease, while others require specialized lubricants with specific viscosity grades.

>All components should be cleaned thoroughly with industrial solvent before installation, ensuring no contamination or metal particles remain inside the housing. After re-lubrication and reassembly, the gearbox housing must be sealed carefully and checked for proper alignment and airtightness.

Professional Methods for Disassembling, Inspecting, and Repairing Industrial Drill Gearboxes

Key Tips to Extend the Lifespan of Industrial Drill Gearboxes

Controlled and Proper Use of the Machine

One of the most important factors in increasing gearbox durability is how the machine is used. Continuous drilling without pauses or applying excessive pressure during operation increases heat and friction, which leads to premature wear of the gears. Professional operators always plan cooling intervals during heavy-duty operations to prevent overheating and maintain long-term performance, a crucial part of effective industrial drill gearbox repair and maintenance.

Preventive Maintenance and Scheduled Servicing

A common mistake among industrial users is ignoring routine service. Many wait until the drill completely fails before checking lubrication or inspecting internal parts. However, a simple inspection every three to six months can prevent costly failures. Checking the condition of gearbox grease or oil, inspecting housing bolts, and testing gear movement should be part of a regular preventive maintenance program.

Proper Storage Conditions

Storing an industrial drill in unsuitable environments, such as damp rooms, dusty workshops, or areas with large temperature fluctuations, directly affects gearbox health. Moisture can cause rust on the gears and shafts, while dust may enter the housing and accelerate wear of moving parts. Using protective cases, storing the drill on proper shelves, and covering gearbox openings with caps significantly reduces these risks.

Choosing the Right Grease and Spare Parts

Using low-quality or incompatible lubricants is one of the main causes of early gearbox failure. Only lubricants recommended by the manufacturer or trusted service centers should be used. The same applies to spare parts. Replacing gears or bearings with non-original components may work temporarily, but it eventually damages other internal parts and shortens the overall lifespan of the gearbox.