What Features Define the Best Magnetic Drill for Steel Hall & Shed Construction?

What Features Define the Best Magnetic Drill for Steel Hall & Shed Construction?

Introduction

In steel hall (shed) construction projects, drilling is not a peripheral or simple task. A significant part of the structure’s execution depends on the quality and precision of these very holes. Heavy I-beams, thick plates, connection plates, and base plates all require precise and safe drilling. This operation is sometimes performed in the workshop, but in many cases, it takes place at the installation site and even at heights. In such conditions, selecting the right Magnetic Drill becomes critical. A machine designed for light workshops usually fails in shed construction projects. Vibration, slipping on the metal surface, motor power loss, or even frequent stoppages are the results of choosing the wrong magnetic drill. The purpose of this article is to closely examine which magnetic drill is suitable for shed construction and what features make a machine truly effective in the actual execution of a steel structure.

Why is Magnetic Drill Selection Important in Shed Construction Projects?

The Difference Between Shed Drilling and Ordinary Workshop Tasks

In light workshop tasks, parts are often fixed on the ground or a workbench, and drilling conditions are more controlled. However, in shed construction, the section thickness is greater, the number of holes is high, and the drilling location is not always in an ideal position. Drilling on long beams, columns, and bracings requires a machine that has both sufficient power and remains stable under various conditions.

The Cost of Mistakes in Selecting a Magnetic Drill for Sheds

A wrong choice doesn’t just mean buying an unsuitable machine. This mistake can lead to project delays, increased tool wear, premature machine failure, and even execution errors. In shed construction projects where delivery time and execution quality are paramount, these costs quickly manifest themselves.

What Features Should a Shed Construction Magnetic Drill Have?

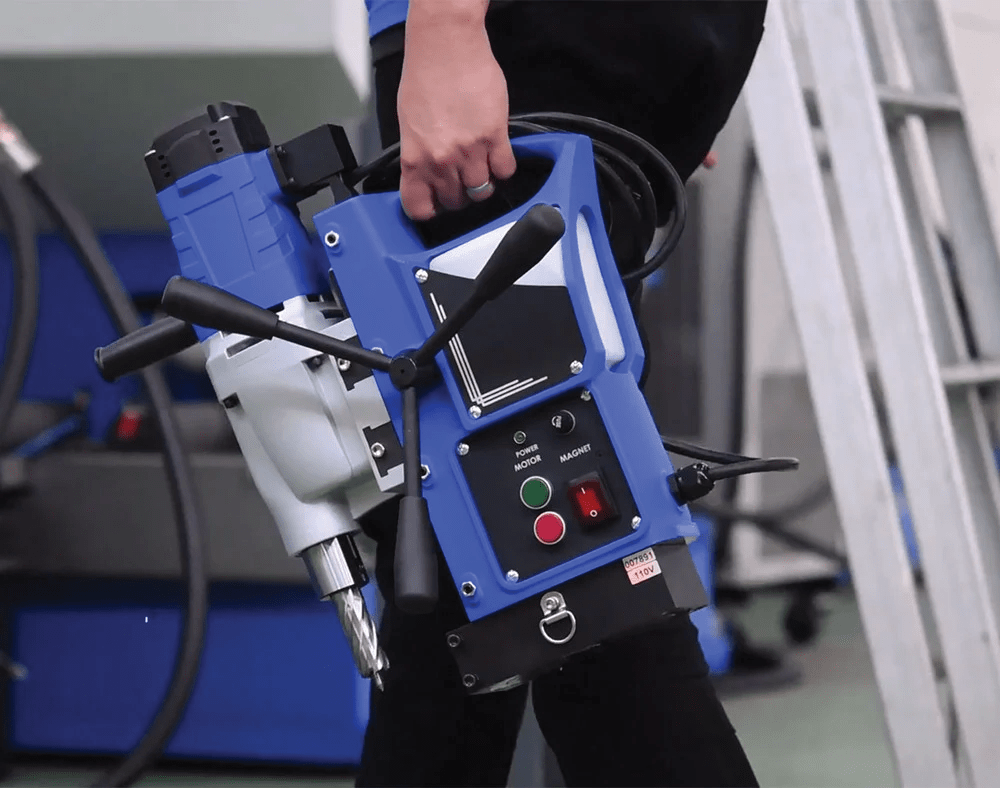

Magnet Power and Its Role in Safety

Magnet power is the first determining factor. The magnetic drill must create a completely stable connection on heavy beams and thick plates. In conditions where drilling is done at heights or on semi-smooth surfaces, the power and design quality of the magnet base play a direct role in work safety and precision.

Motor Power and Torque Suitable for Beams and Thick Plates

Motor power is not just a number on a catalog. In drilling heavy sections, the motor must supply the necessary torque without power loss. A machine that fails under load causes unwanted stops and reduces execution speed in shed construction projects.

Machine Weight and Control at Heights

In shed construction projects, the magnetic drill’s weight must be balanced. A very light machine might not have enough stability, and an overly heavy machine makes control difficult. This balance is especially important in vertical drilling and operations at heights.

Stability During Vertical and Horizontal Drilling

Drilling in a shed is not done only on horizontal surfaces. In many spots, the machine must work vertically or even overhead (inverted). A suitable magnetic drill for shed construction must perform stably in all these positions and transfer pressure uniformly.

What Features Should a Shed Construction Magnetic Drill Have?

Under What Conditions Does a Magnetic Drill Have Maximum Efficiency?

Drilling Heavy Shed Beams

Beams are the main part of the shed structure. Precise drilling on these sections has structural importance. A magnetic drill that works without vibration or deviation on a heavy beam increases both execution speed and connection quality.

Drilling Connection Plates and Base Plates

Connection plates and base plates usually have high thickness. Drilling these parts requires appropriate torque and high stability. The combination of magnet power and motor power becomes doubly important here.

Drilling at the Installation Site

In many projects, drilling is performed after the structure is installed. In these conditions, moving the piece is impossible, and the machine must adapt to the execution conditions. A magnetic drill suitable for shed construction is designed exactly for such situations.

Real Shed Construction Conditions and Impact on Drill Selection

Shed construction is often done outdoors with limited peripheral equipment. Many beams are pre-painted or do not have perfectly smooth surfaces. In such conditions, if the magnet base and machine design are weak, even a professional operator will face problems. On the other hand, the volume of drilling in shed projects is usually high, and the machine must operate continuously. Drills designed for light work overheat or suffer performance drops in these conditions. Therefore, selecting a magnetic drill suitable for shed construction must be based on actual execution realities, not just catalog specifications.

The Difference Between Shed Needs and Regular Steel Frameworks

In regular steel frameworks, many holes are drilled in the workshop before installation. This means conditions are more stable and controllable. But in shed construction, a large part of drilling is done on-site and at heights. This difference makes machine stability, operator control, and safety more important. A magnetic drill suitable for light steel frameworks does not necessarily work for shed construction. This difference is the main reason for the need to select a targeted magnetic drill for shed construction.

The Difference Between Shed Needs and Regular Steel Frameworks

Key Criteria for Selecting a Magnetic Drill for Shed Construction

When choosing a magnetic drill for shed projects, attention to these points is essential:

- Real and stable magnet power for secure connection on beams and thick plates.

- Appropriate motor power for continuous drilling without performance loss.

- Magnet base design that remains stable even on semi-smooth surfaces.

- Balanced weight for better control at heights.

- Performance stability in horizontal, vertical, and overhead modes.

- Compatibility with industrial Annular Cutters specific for thick steel.

- Durability of mechanical parts for long-term work in the project.

These criteria together determine whether a magnetic drill is truly suitable for shed construction or just looks strong on paper.

Comparison: Shed Construction Magnetic Drill vs. Ordinary Models

| Feature | Ordinary Magnetic Drill | Magnetic Drill for Shed Construction |

| Magnet Power | Average | High and Stable |

| Motor Power | Limited | Suitable for Continuous Work |

| Application | Light Workshop | Shed Projects |

| Durability | Ordinary | High |

| Safety at Height | Limited | Reliable |

Frequently Asked Questions (FAQ)

Is every magnetic drill suitable for shed construction?

No. Many models are designed for light tasks and do not perform optimally in shed projects.

What is the minimum magnet power for shed execution?

The magnet power must be enough for the machine to remain completely stable on beams and thick plates. Base design and execution conditions also play a role.

Is a light or heavy magnetic drill better?

Balance is key. The machine must be heavy enough to remain stable, but not so heavy that control at heights becomes difficult.

Is a magnetic drill safe at heights?

Yes, if the right machine is selected and used correctly. Magnet power and base design play a key role in safety.

Frequently Asked Questions About Magnetic Drills

Conclusion and Right Selection

In shed construction, the magnetic drill is a key execution tool. A wrong choice can lead to reduced work speed, increased errors, and safety risks. Conversely, consciously selecting a magnetic drill suitable for shed construction turns the drilling process into a controllable and reliable task.

Reliable Purchase from Rahmani Magnetic Drill Store

If you are looking for a magnetic drill suitable for shed construction, choosing the store is as important as choosing the machine. At Rahmani Magnetic Drill Store, a collection of industrial magnetic drills from reputable and quality European brands is offered, specifically selected for construction and shed projects. The advantage of buying from Rahmani is not just model variety, but specialized pre-purchase consultation, genuine product warranty, and specialized repairs. With this consultation, you select a machine tailored to section thickness, drilling volume, and your project’s execution conditions.