Comprehensive Buying Guide: Low Profile Magnetic Drills; The Specialist for Drilling in Impossible Spaces

Comprehensive Buying Guide: Low Profile Magnetic Drills; The Specialist for Drilling in Impossible Spaces

Introduction

In the world of massive industrial projects, things don’t always go according to plan. Imagine you are assembling the steel skeleton of a tower, or you are responsible for repairing the chassis of a mining truck. Suddenly, you face a serious challenge: you need to create a precise hole in a beam or metal piece, but the distance between that piece and the wall or ceiling above is less than 20 centimeters. Standard magnetic drills, with a height of about half a meter, cannot even fit into this space. Handheld drills lack the necessary power and precision for drilling large diameters. This is the point where projects stall, time is wasted, and costs escalate. However, the solution to this technical deadlock is the use of a tool specifically designed for these conditions: the Low Profile Magnetic Drill.

This article is not a regular buying guide; rather, it is a technical class for workshop managers, supervising engineers, and industry professionals who want to make the impossible possible with modern equipment. In this content, we will conduct a complete dissection of the Low Profile Magnetic Drill, examine its advantages and disadvantages, and teach the golden tips for its maintenance.

What is a Low Profile Magnetic Drill and How is its Engineering Different?

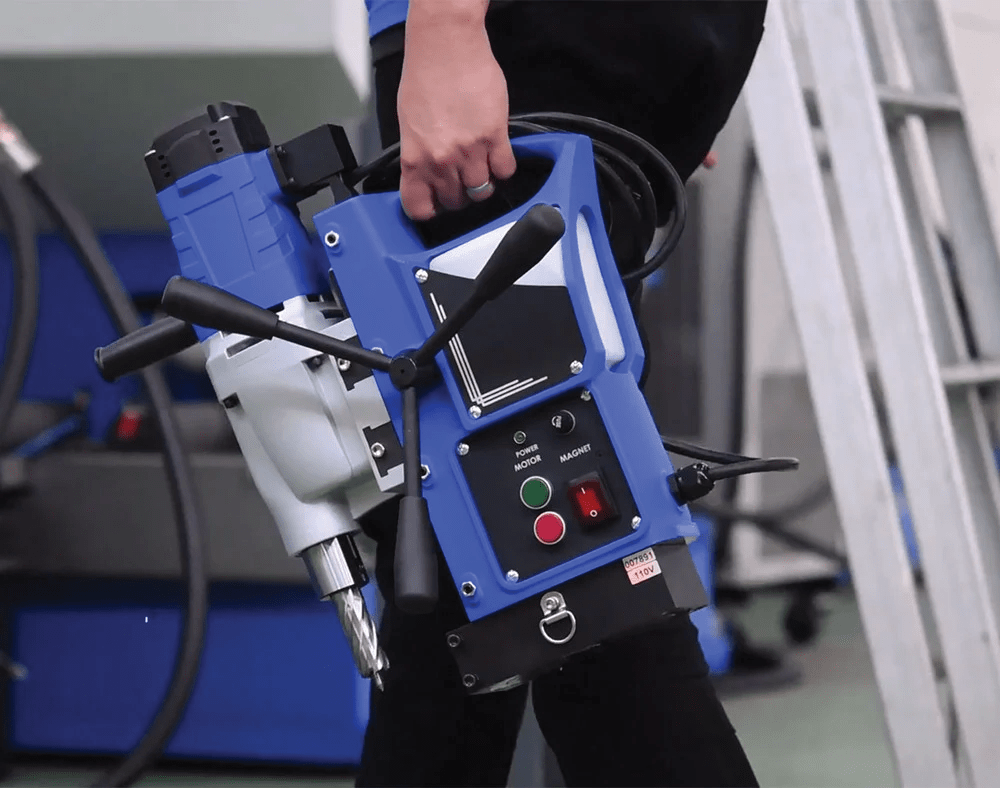

For a better understanding, we must first look at the structure of ordinary drills. In standard drills, the motor is positioned vertically and aligned with the drill bit axis. This design results in a high overall height for the machine. However, in the Low Profile Magnetic Drill, engineers have intelligently changed the structure by placing the motor on its side. In these machines, the rotational force of the motor is transferred to the drill axis via a 90-degree gearbox. This change in angle drastically reduces the overall height of the machine (usually between 15 to 20 centimeters). This compact design gives the operator excellent maneuverability without compromising drilling power.

Technical Analysis of the Power Transmission Mechanism

You might ask, “Does changing the motor angle cause a drop in power?” The answer is no. The Low Profile Magnetic Drill uses advanced bevel or helical gears that transmit torque with minimal energy loss. In fact, due to the proximity of the machine’s center of gravity to the workpiece, there is less vibration compared to vertical models, which itself increases cutting efficiency.

What is a Low Profile Magnetic Drill?

Why Do Modern Industries Have an Urgent Need for Low Profile Magnetic Drills?

The need for this tool is not solely limited to “tight spaces”. Using a low-profile magnetic drill offers numerous technical and safety advantages, which we will deeply elaborate on:

Mastery Over Inaccessible Spaces

The device is most used in industries where component density is high:

- Heavy Vehicle Industry: Drilling on the chassis of trailers and trucks without the need to dismantle the cabin or axle.

- Metal Structures and Bridge Construction: Drilling inside the web of H-beams or box sections where the flange distance is small.

- Oil and Petrochemical Industries: Working amidst dense pipelines and flanges where access is difficult.

Ergonomics and Operator Health

Working in tight spaces with inappropriate tools puts significant strain on the operator’s spine and wrist. The Low Profile Magnetic Drill minimizes operator fatigue with its ergonomic handles and balanced weight. Also, using a “ratchet handle” instead of conventional rotary handles allows the operator to perform the drill feed operation with minimal hand movement.

Superior Magnetic Stability and Adhesion

One of the principles of physics is: “The lower the center of gravity, the greater the stability”. In the Low Profile Magnetic Drill, the distance from the motor to the magnet surface is very short. This feature significantly reduces the risk of the machine detaching from the workpiece during horizontal (on the wall) or inverted (under the ceiling) drilling. This translates to 100% safety in sensitive projects.

Why Do Modern Industries Need Low Profile Magnetic Drills?

Step-by-Step Guide to Choosing the Best Low Profile Magnetic Drill

The tool market is full of various brands and models. But to choose an efficient machine that will last for years on your workshop’s frontline, you must pay attention to the following five technical parameters:

Detailed Dimension Check (Beyond the Catalog)

Many buyers only look at the height of the machine body. But the key point is the operational height. You must consider the machine’s height when the annular cutter and pilot pin are installed on it. Sometimes installing a long cutter increases the overall height by 5 cm, preventing the machine from fitting in the desired location. Always precisely measure your workspace and compare it with the machine’s “ready-to-operate” dimensions before buying.

Feed Handle Portability

In tight spaces, the right side of the machine might be blocked. A professional Low Profile Magnetic Drill should have the capability to install the feed handle (drilling lever) on both the left and right sides. This simple feature is lifesaving in critical situations.

Internal Cooling System

In confined spaces, manual pouring of coolant (soap-water) is both difficult and messy. Advanced machines have a separate reservoir and an internal pump that delivers the fluid from inside the spindle to the tip of the cutter. This system not only keeps the environment clean but also doubles the cutter’s lifespan.

Tool Holder Type (Weldon vs. Others)

Most low-profile magnetic drills, to save space, lack a chuck and use a direct tool holder system. The most common standard globally and in Iran is the 19mm standard (Weldon). Ensure your machine supports this standard so you don’t face issues procuring cutters.

Motor Power and Speed Control System

If you plan to work on hard alloys (like stainless steel) or perform tapping operations with this machine, be sure to select a model that has a dimmer (speed control) and a powerful gearbox. Constant speed is not suitable for all metals.

Technical Challenges and Limitations of the Low Profile Magnetic Drill

Technical honesty requires us to discuss the limitations alongside the advantages. This machine, with all its capabilities, is not suitable for every job:

Cutter Length Restriction:

Due to the compact design, the stroke (the amount the cutter travels down) is limited in these machines. You usually cannot use cutters longer than 3 or 5 centimeters. If you need to drill very thick plates (e.g., 10 cm), this machine is not the appropriate choice.

Specialized Repairs:

The angled gearbox mechanism has more complexity than direct gearboxes. If faulty, repairing a Low Profile Magnetic Drill requires a skilled specialist and should not be opened by novices.

Inability to Use Standard Drill Bits:

These machines are specifically designed for annular cutters. Installing conventional twist drills (straight shank or taper shank) requires special adapters, which often lack technical justification as they increase the height.

HSE Safety Tips Specific to Working in Tight Spaces

Working with powerful electric tools in a confined space carries its own specific dangers. Observing the following points is essential for protecting the operator’s life and the machine’s health:

Machine Restraint:

Even with a strong magnet, when working at height or in tight spaces, always use a safety chain or strap. This strap prevents the machine from falling onto the operator in case of a sudden power outage.

Power Cable Management:

In confined environments, there is a risk of the power cable snagging on sharp parts and tearing. Secure the cable path before starting work.

Swarf Evacuation:

Hot and sharp metal chips (swarf) in a confined space may hit the operator’s face or body. Using safety glasses and covering work clothes, as well as using magnetic pens for continuous swarf collection, is essential.

HSE Safety Tips Specific to Working in Tight Spaces

Guide to Maintenance and Increasing Machine Lifespan

The Low Profile Magnetic Drill, due to its application, is more exposed to dust and metal chips. To ensure your machine works like new for years, follow this maintenance routine:

Cleaning the Rails:

After every use, clean the machine’s slide rails with compressed air and lubricate them with a penetrating spray. The penetration of fine metal chips into the rails is the killer of the machine’s accuracy.

Checking Motor Brushes:

These machines’ motors are usually high-speed. Check the condition of the motor brushes every 100 operating hours and replace them if worn out.

Coolant Tank Drainage:

If you are not using the machine for a long time, drain the coolant reservoir to prevent scaling and blockage of internal hoses.

Frequently Asked Questions (FAQ)

Can a low-profile magnetic drill perform tapping?

This depends on the machine model. For tapping, the machine must have two vital features: first, reverse rotation capability (left/right rotation) to extract the tap; and second, torque control to prevent tap breakage. Not all low-profile models have this capability. Be sure to emphasize “Tapping capability” when purchasing.

What is the maximum drilling size?

The most common Low Profile Magnetic Drill models in the Iranian market can drill up to 35 or 36 millimeters in diameter, which is sufficient for 90% of industrial jobs. Heavier models for diameters of 50 millimeters and above also exist, which have more weight and price.

Can long cutters be used?

Generally, no. The stroke (travel distance) of these machines is short. If you use a very long cutter, the cutter tip rests on the workpiece, but the machine still lacks sufficient room for maneuvering and starting the drill. Always use cutters with the standard 30mm length unless the machine catalog permits the use of 50mm cutters.

Conclusion and Final Word: A Reliable Purchase for Sensitive Projects

The Low Profile Magnetic Drill is not a luxury decorative tool; it is a “true problem solver” in the industry. You might only need it a few times during a project, but those few times can resolve bottlenecks and prevent several days of work stoppage and millions in losses. Investing in a quality machine is essentially an investment in your “time” and “technical credibility”.

However, in the crowded tool market, distinguishing genuine from fake and selecting a model that precisely matches your needs is challenging. This is where experience and expertise matter.

At Rahmani Magnetic Drill Store, we are not merely sellers of a toolbox; we consider ourselves your technical partner in projects. Relying on years of experience in the industrial tool market, we have curated a selection of the best Low Profile Magnetic Drill brands so that you can be confident about “quality,” “genuine warranty,” and most importantly, “spare parts supply”.

If you still have doubts about choosing the right model or don’t know which machine suits your workshop conditions, contact the expert team at Rahmani Magnetic Drill Store now. We are ready to propose the best engineering solution tailored to your budget.