What Is a Magnetic Drill?

What Is a Magnetic Drill?

An In-Depth Guide for Industrial Professionals

Magnetic drills have become indispensable in modern metal fabrication, construction, and industrial maintenance. Renowned for their precision and efficiency, these specialized tools use powerful electromagnets to securely attach to metal surfaces, ensuring stable and accurate drilling even in challenging environments. This article provides a comprehensive overview of magnetic drills—from their basic introduction and applications to detailed insights into their working mechanisms, types, selection criteria, and benefits.

Introduction

A magnetic drill, often referred to as a “mag drill,†is a portable drilling machine equipped with an electromagnet that firmly attaches to ferrous surfaces. This unique design allows for drilling holes with high precision and minimal vibration, making it ideal for heavy-duty tasks. Designed for both manual and automated use, magnetic drills are essential for professionals who demand accuracy and durability on the job site.

Applications

Magnetic drills are widely used across various industrial sectors. Their primary applications include:

- Metal Fabrication: Efficiently drill precise holes in steel beams, plates, and frames.

- Construction: Ideal for tasks such as installing anchors, conduits, and structural reinforcements.

- Maintenance & Repair: Frequently employed in on-site repairs where stability and precision are crucial.

- Pipeline & Infrastructure Projects: Used for creating clean, exact holes in large metal structures.

Due to their versatility and reliability, magnetic drills are a staple tool in many industrial operations, making them a go-to choice for professionals in metalworking and construction.

How It Works

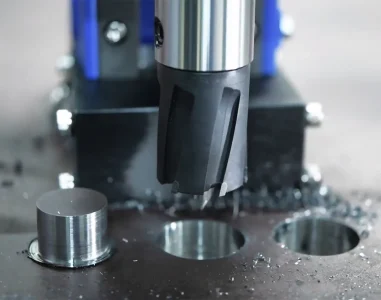

At the heart of a magnetic drill is its powerful electromagnet. When activated, this magnet securely clings to a metal surface, creating a stable platform for drilling. Key operational features include:

- Electromagnetic Clamping: The electromagnet provides a strong, adjustable hold, ensuring that the drill remains fixed during operation.

- Precision Drilling: The design minimizes vibration, allowing for smooth, clean cuts even in hard metals.

- Adjustable Speed and Pressure: Operators can fine-tune drilling parameters to suit different materials and thicknesses, ensuring optimal performance.

- Safety Mechanisms: Many models include automatic shut-off features if the magnetic hold is compromised, safeguarding both the tool and the operator.

These characteristics ensure that magnetic drills deliver both high efficiency and reliability, even under demanding industrial conditions.

Types of Magnetic Drills

Magnetic drills come in various models designed to meet the specific requirements of different industrial applications. In addition to the basic distinctions of standard versus heavy-duty and portable versus stationary, modern magnetic drills are available in specialized configurations:

Standard & Heavy-Duty Models

- Standard Magnetic Drills:

These are ideal for routine drilling tasks on flat, ferrous surfaces. They offer essential electromagnetic clamping and adjustable speed settings. - Heavy-Duty Magnetic Drills:

Built for large-scale industrial projects, these drills feature enhanced magnetic strength, robust construction, and advanced safety features to handle thick or heavy metal work.

Advanced Variants

- Automatic Magnetic Drills:

Equipped with automatic control systems, these models can self-adjust drilling parameters, maintain consistent speed and pressure, and often include features like auto-start/stop when the magnetic hold is compromised. They are designed to boost productivity and reduce operator fatigue during continuous operation. - Universal Magnetic Drills:

Designed for versatility, universal models can be adapted for various applications and materials. They offer adjustable settings that allow them to work effectively on different thicknesses and types of metals, making them a flexible choice for mixed-material projects. - Compact Magnetic Drills:

These are engineered for portability and ease of use in tight spaces or hard-to-reach areas. Despite their smaller size, compact models do not compromise on performance, providing sufficient magnetic power and precision for many field applications. - Endurance Magnetic Drills:

Optimized for prolonged, heavy-duty operation, endurance models are constructed with high-grade materials and enhanced cooling systems. They are specifically designed to maintain performance over extended periods, reducing downtime in continuous production environments.

Selection Criteria for Magnetic Drills

When choosing a magnetic drill, professionals should consider the following key criteria:

- Magnetic Strength: Ensure the drill’s electromagnet can securely hold the tool to the metal surface, especially on uneven or inclined surfaces.

- Drilling Capacity: Verify that the tool is capable of handling the material thickness and type specific to your project.

- Speed and Torque Control: Look for drills with adjustable speed settings and sufficient torque to handle various drilling tasks efficiently.

- Durability and Build Quality: Opt for models constructed with high-grade materials that can withstand rigorous industrial use.

- Safety Features: Select drills that incorporate automatic safety shut-offs and overload protection to minimize risk during operation.

For expert recommendations and a wide selection of high-quality magnetic drills, professionals can turn to Rahmani Magnetic Drill Store. Renowned for its specialization in magnetic drills and related repair services, Rahmani Magnetic Drill Store provides trusted advice and premium products tailored to industrial needs.

Advantages of Using Magnetic Drills

Magnetic drills offer several benefits over conventional drilling methods:

- Enhanced Precision: Deliver clean, accurate holes with minimal vibration.

- Improved Efficiency: Faster drilling speeds reduce downtime and increase overall productivity.

- Versatility: Adaptable for various industrial applications, from heavy-duty construction to fine metal fabrication.

- Cost-Effectiveness: Lower maintenance requirements and extended tool lifespan contribute to reduced operational costs.

- Safety: Built-in safety features ensure a secure operation, protecting both the operator and the equipment.

Conclusion

Magnetic drills represent a sophisticated solution for modern industrial drilling applications. Their advanced design, combined with precise operational control and robust safety features, makes them an essential tool for professionals across a wide range of industries. By understanding the types, operational mechanisms, selection criteria, and advantages of magnetic drills, professionals can optimize their work processes and enhance productivity.

For those seeking top-quality magnetic drills and expert repair services, Rahmani Magnetic Drill Store stands as a trusted partner, offering industry-leading products and specialized technical support to meet the demands of modern industrial applications.